- Joined

- Dec 24, 2020

- Messages

- 1,040

Okay, this one is entirely on me, and now I'm looking for a bit of help. I'm far from an electrician, so I'll apologize in advance if I use a wrong term/description.

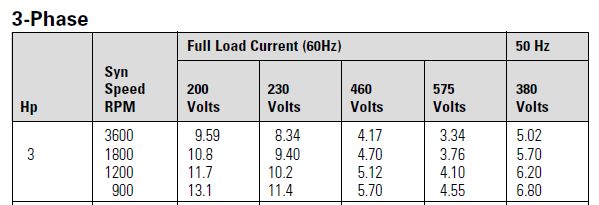

I've been working through evaluating my recent project lathe purchase (Clausing 6913) to see what's good, what needs to be fixed, etc. The machine was originally set for 460V and I have 230V from my RPC. The machine is configured with a single-phase F/N/R drum switch and a magnetic motor starter as well as a control transformer to provide the 120V for the drum switch. I reconfigured the motor leads and connections for 230V as well as the control transformer connections and fired up the RPC...everything seemed to work, but I only ran it for a short period of time.

My next step was to try the variable speed system and had the machine running when the overload tripped. I figured I did something wrong in the wiring so I checked the connections back to the RPC, reset the overload and it started back up. A few minutes later the overload tripped again (this should have been a clue). I pulled the cover off the magnetic switch box and started checking connections there. Reset the overload and it started up again....ran for a few minutes and tripped. At this point I remembered I hadn't even thought about the heaters in the thermal overload relays. Sure enough, the heaters were 4.5A and the motor draws 9A. Problem is, the overload won't reset now. I'm assuming the multiple resets so quickly damaged the melting alloy pot, or something similar. Before I start pulling things apart I figured I would ask the experts. I also can't see any information on the side of the OL relays to see if I can find replacements....might have to remove them for that. The relays use type H heaters if that helps.

If anybody can point me in the right direction on the OL relays to see if there's anything that might be repaired/replaced, and what model they might be, or if there's something that would be a direct replacement. Here are a couple of pics....the overall layout and closeup of the OL relays.

I've been working through evaluating my recent project lathe purchase (Clausing 6913) to see what's good, what needs to be fixed, etc. The machine was originally set for 460V and I have 230V from my RPC. The machine is configured with a single-phase F/N/R drum switch and a magnetic motor starter as well as a control transformer to provide the 120V for the drum switch. I reconfigured the motor leads and connections for 230V as well as the control transformer connections and fired up the RPC...everything seemed to work, but I only ran it for a short period of time.

My next step was to try the variable speed system and had the machine running when the overload tripped. I figured I did something wrong in the wiring so I checked the connections back to the RPC, reset the overload and it started back up. A few minutes later the overload tripped again (this should have been a clue). I pulled the cover off the magnetic switch box and started checking connections there. Reset the overload and it started up again....ran for a few minutes and tripped. At this point I remembered I hadn't even thought about the heaters in the thermal overload relays. Sure enough, the heaters were 4.5A and the motor draws 9A. Problem is, the overload won't reset now. I'm assuming the multiple resets so quickly damaged the melting alloy pot, or something similar. Before I start pulling things apart I figured I would ask the experts. I also can't see any information on the side of the OL relays to see if I can find replacements....might have to remove them for that. The relays use type H heaters if that helps.

If anybody can point me in the right direction on the OL relays to see if there's anything that might be repaired/replaced, and what model they might be, or if there's something that would be a direct replacement. Here are a couple of pics....the overall layout and closeup of the OL relays.