The front chip guard I made a while back has worked well so I made a rear chip guard too that attaches with magnetic brackets to the rear of the milling table for easy removal.

Unlike the front chip guard which has to be lifted off the table when it's time to change setup the rear chip guard will most likely stay in place for most operations.

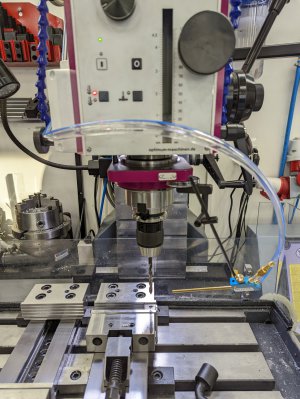

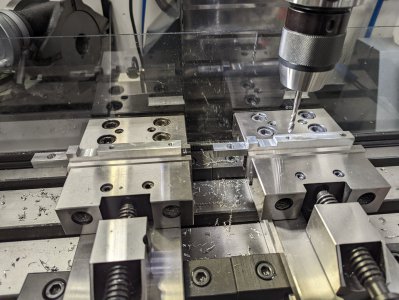

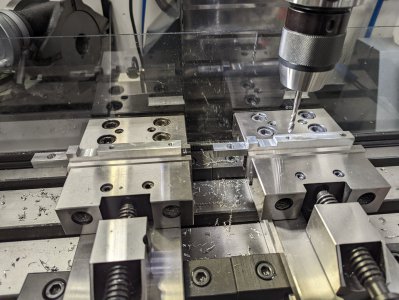

Started by bending a sheet of polycarbonate and then milling out pocket so that it won't interfere with milling head.

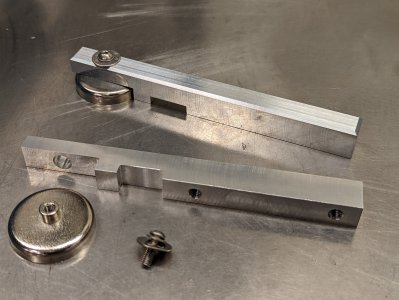

Milling the brackets.

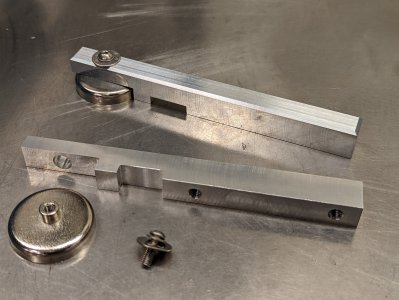

Attaching the magnets (some cheap magnets meant for small hooks https://www.biltema.se/en-se/tools/tool-storage/tool-holders/magnetic-hooks-10-pcs-2000035930).

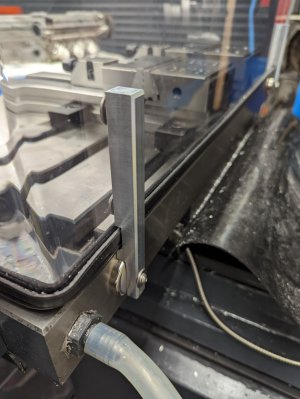

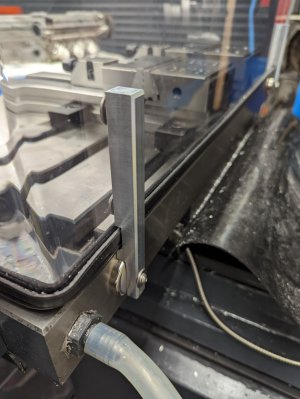

Attaching the brackets to the polycarbonate sheet.

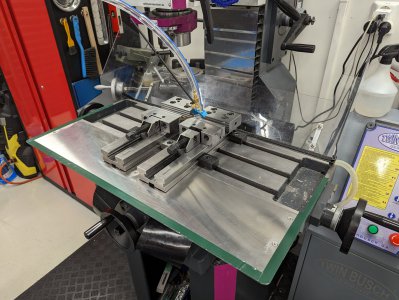

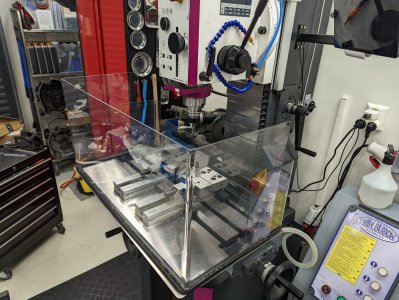

Rear chip guard assembled and installed.

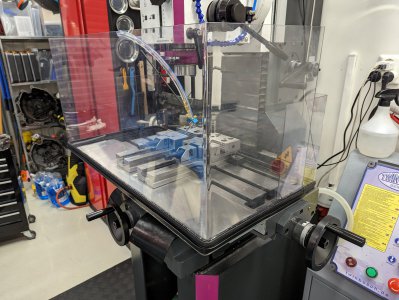

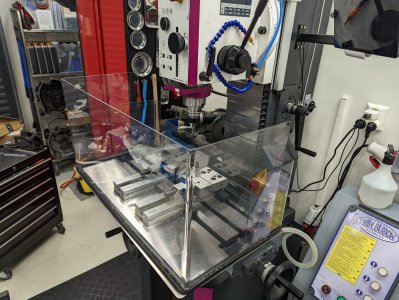

This is how it look with both the front and rear chip guards installed on the mill.

The large overlap between the front and rear chip guards is so that I still get a decent side coverage when only one of the chip guards.

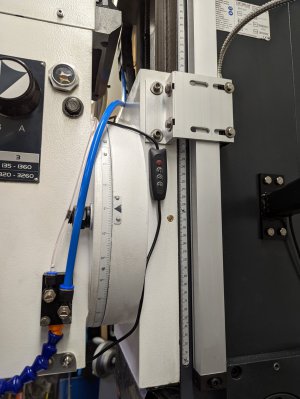

While it was at it I replaced the handles for locking the axis. I never liked those ratchet type ones that came with the machine, I find the knob style ones much more ergonomic.

Unlike the front chip guard which has to be lifted off the table when it's time to change setup the rear chip guard will most likely stay in place for most operations.

Started by bending a sheet of polycarbonate and then milling out pocket so that it won't interfere with milling head.

Milling the brackets.

Attaching the magnets (some cheap magnets meant for small hooks https://www.biltema.se/en-se/tools/tool-storage/tool-holders/magnetic-hooks-10-pcs-2000035930).

Attaching the brackets to the polycarbonate sheet.

Rear chip guard assembled and installed.

This is how it look with both the front and rear chip guards installed on the mill.

The large overlap between the front and rear chip guards is so that I still get a decent side coverage when only one of the chip guards.

While it was at it I replaced the handles for locking the axis. I never liked those ratchet type ones that came with the machine, I find the knob style ones much more ergonomic.

Last edited: