- Joined

- Jan 7, 2016

- Messages

- 3,278

Well shucks.....

Right Aukai!? I was right there with you... From "Yippeeee, A new gadget for my shop" to an immediate balloon pop of "dangit, that looked soooo cool."

LOL

Well shucks.....

"Not available online"Lee Valley Tools has them at $62.50 USAD. That's about $2.00 US

www.travers.com

www.travers.com

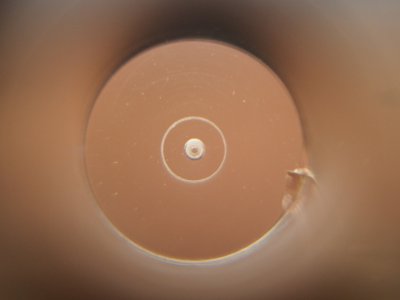

To deal with parallax, wouldn't it make sense to make an aperture sight (a ring mounted to a rod in a parallel plane above the jig) so that your angle of incidence and focal distance are always the same? For you old guys, you could even put a magnifying diopter in the aperture. Seems easy enough. Also, would a groove and a quality o-ring reduce bore play to a tolerable level (pun definitely intended)? I've never used an optical punch, but it seems like the shortcomings can be overcome or reduced with a little bit of mechanic-ing.

Weldo- you might consider making a replacement lens and using a tiny point in the center.