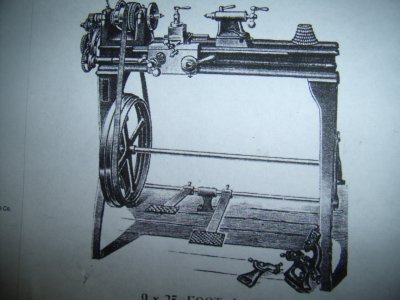

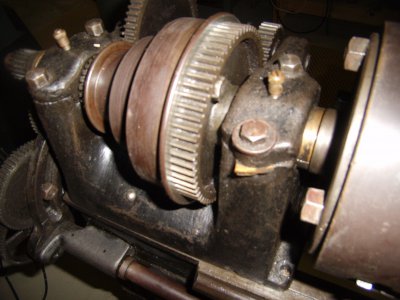

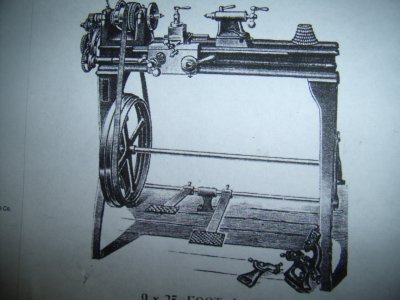

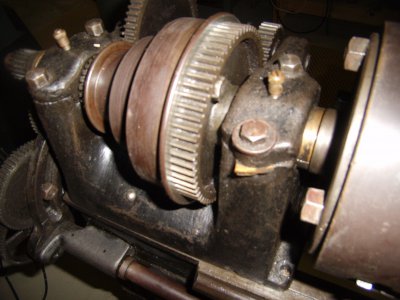

Hi, i have posted this lathe in Other Lathe Brand, I am thinking I could reach more people here. The picture are of a Carroll Jamieson 1906,( treadle, foot powered or pedal?), lathe. the only number I can find is on the lead screw holder by headstock, A00. She missing the treadle assembly and a broken handle on tailstock. I have no ideals where to start. I believe this to be a special lathe, that one day I would like to see it in on local historic museum. This is for all generation and generation to come. Help is what I need, so please give any advice you can on where to start, getting parts, stripping paint or anything you can think of. Thanks Chester