- Joined

- Oct 30, 2012

- Messages

- 157

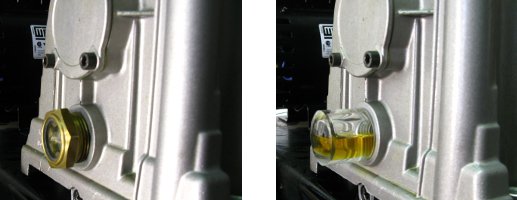

Both my VN12 and my Clausing 6913 have plastic (looking) oil level indicators. I have been thinking of cooking up some kind of replacement inpired by this: http://www.gis-store.net/3-D-BullsEye_c86.htm

Its a "3d" oil sigh indicator that really looks like an acrylic jar poking out of your machine a bit. I can't decide if the poke-out (and related smash danger) would be worth the enhanced visibility.

Any opinions?

Its a "3d" oil sigh indicator that really looks like an acrylic jar poking out of your machine a bit. I can't decide if the poke-out (and related smash danger) would be worth the enhanced visibility.

Any opinions?