It seems the oil-filled run capacitor in my rotary phase converter spilled its guts. When I went to start it, it started to spin but never got up to speed. There was oil splattered everywhere when I opened it up.

Unfortunately the info printed on the capacitor has slightly worn off. It looks like it says 50/15 uF 330VAC. I think the model number is 97F4747 FB but I wasn't able to find anything with that.

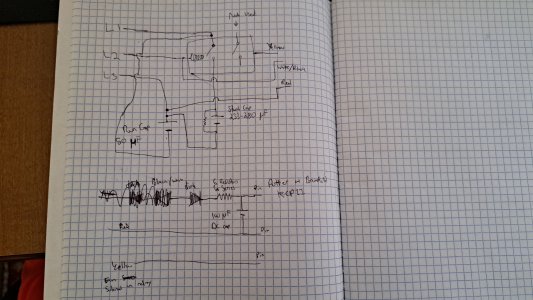

From my quick research, dual capacitance caps are mainly used in HVAC where one terminal is used for the compressor and the other the fan, with the third being common. Only the "C" and "HERM" terminals were hooked up, the "FAN" wasn't used. Can I replace it with a regular oil capacitor with one capacitance? Which capacitance do I need, 15 uF or 50 uF?

Unfortunately the info printed on the capacitor has slightly worn off. It looks like it says 50/15 uF 330VAC. I think the model number is 97F4747 FB but I wasn't able to find anything with that.

From my quick research, dual capacitance caps are mainly used in HVAC where one terminal is used for the compressor and the other the fan, with the third being common. Only the "C" and "HERM" terminals were hooked up, the "FAN" wasn't used. Can I replace it with a regular oil capacitor with one capacitance? Which capacitance do I need, 15 uF or 50 uF?