I like the spray pattern these make. I ran at 30psi for testing with water and it worked great. I can't test it on a machine as my lathe isn't here yet, but it seems like a good option with a wide range of adjustment.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Nice spray mist system for the mill / lathe

- Thread starter Jake2465

- Start date

- Joined

- Oct 24, 2013

- Messages

- 149

If you meant to send an image nothing showed up here. Also, I wouldn't use pure water as a coolant because it'd cause rust problems. (You may already be planning to use a non-corrosive coolant, if so, disregard my last comment!) Enjoy your new lathe!

- Joined

- Dec 27, 2017

- Messages

- 340

If regulated air pressure is provided to the mist system, then the next thing needed is a needle valve for the water in. That is a very important part of the system because it needs fine adjustments. Before I purchased those twin needle sprayers, I considered getting a inline needle valve form a OS Max engine because they could adjust flow rates pretty well. I ended up not doing that because those things are in the neighborhood of around $40 each. But, if you already have enough air flow for the system to draw water, then the only thing left is something to finely regulate that water flow and that's pretty much it.

Jake,

Having the fluid needle valve in the block is another reason I got the two-valve unit. Trying to adjust the fluid/air mix at the mister tip was always a pain. Especially if I needed to adjust it while a CNC program was running...too close to a spinning bit.

Ken

Having the fluid needle valve in the block is another reason I got the two-valve unit. Trying to adjust the fluid/air mix at the mister tip was always a pain. Especially if I needed to adjust it while a CNC program was running...too close to a spinning bit.

Ken

- Joined

- Nov 25, 2015

- Messages

- 8,319

So my thinking was both regulated and the 2 valve. The same way a conversion HVLP sprayer has regulated air, plus a air adjustment screw to fine tune the volume, seems like you can take high pressure dial it in close, and adjust it even finer. A ball valve for on and off seems like a good idea too.If regulated air pressure is provided to the mist system, then the next thing needed is a needle valve for the water in. That is a very important part of the system because it needs fine adjustments. Before I purchased those twin needle sprayers, I considered getting a inline needle valve form a OS Max engine because they could adjust flow rates pretty well. I ended up not doing that because those things are in the neighborhood of around $40 each. But, if you already have enough air flow for the system to draw water, then the only thing left is something to finely regulate that water flow and that's pretty much it.

- Joined

- Feb 7, 2011

- Messages

- 5,039

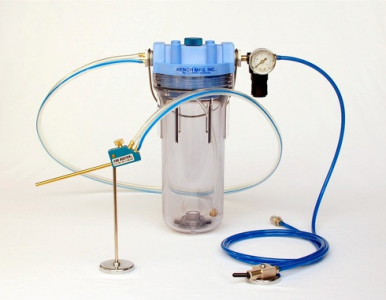

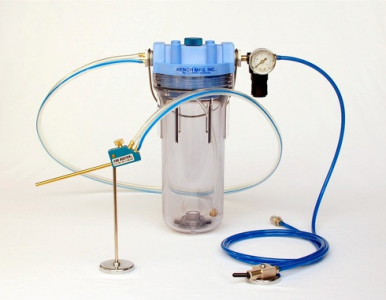

This system will be ideal to use on a fog buster/ micro drops system.

http://fogbuster.com/

https://www.hobby-machinist.com/threads/no-fog-coolant-mister.19957/

http://fogbuster.com/

https://www.hobby-machinist.com/threads/no-fog-coolant-mister.19957/

Last edited:

- Joined

- Dec 27, 2017

- Messages

- 340

So my thinking was both regulated and the 2 valve. The same way a conversion HVLP sprayer has regulated air, plus a air adjustment screw to fine tune the volume, seems like you can take high pressure dial it in close, and adjust it even finer. A ball valve for on and off seems like a good idea too.

I agree

The ball valve would be good if the compressor would always be pressurized and the ball valve could act like the on/off switch.

- Joined

- Jul 2, 2014

- Messages

- 7,594

This YouTube video from Tom Lipton (Oxtoolco) from 2013 shows an interesting way of setting up a mist coolant system. Relevant part starts at about 9:22 and goes to 19:30. Pressurizing the coolant side is the way to make these things less fussy. The siphon system works, but is less than ideal. Personally, I would leave the air side of the system alone, using the liquid needle valve just like it is, and then just try for creating low and adjustable pressure so it is no longer a siphon system, but rather is just coolant under low pressure to the mister unit. The plastic two liter soda bottles are cheap, will not explode under any reasonable shop pressure, are easy to see the remaining coolant level, hold a good amount of coolant, and are quick to change out as required.