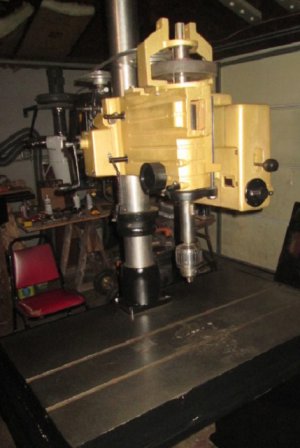

I really didn't need another drill press since I currently have a 17" Delta & a 20" Walker Turner!

However, I seen this Powermatic 1200HD at a local on-line auction & I was able to get it at a good price.

Getting it into my normal 2-car garage was a bit of a challenge.

I had to disassemble the head from the base to get it into the garage.

Once inside I reassembled it & placed it next to the other drill presses.

Doug

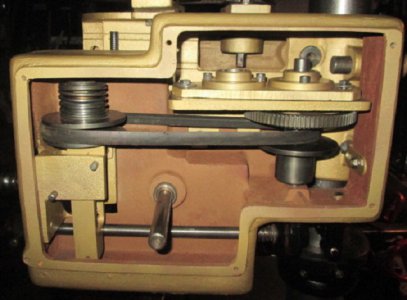

However, I seen this Powermatic 1200HD at a local on-line auction & I was able to get it at a good price.

Getting it into my normal 2-car garage was a bit of a challenge.

I had to disassemble the head from the base to get it into the garage.

Once inside I reassembled it & placed it next to the other drill presses.

Doug