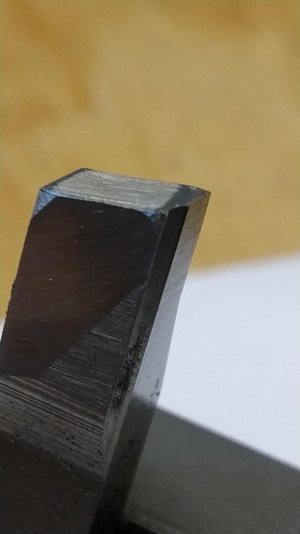

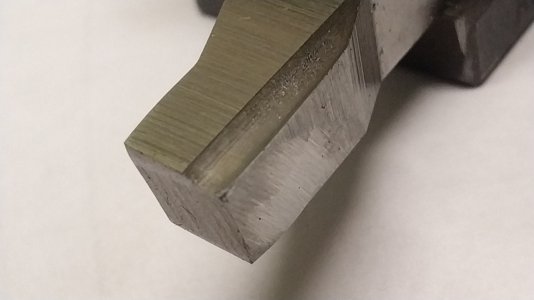

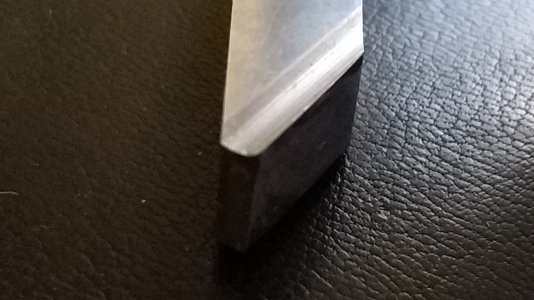

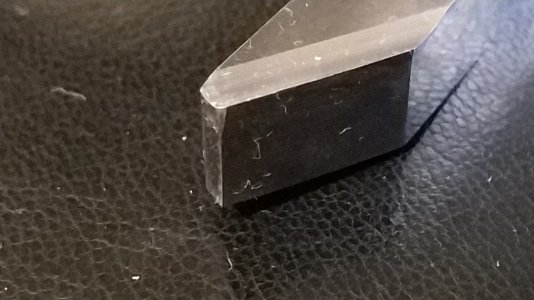

Well, I made something with my lathe : alu PCB holder with a magnet underneath it. The finish is nice and I want more of this by grinding a HSS tool for turning and giving better finishes on aluminum.

I am not sure if the ISO 10 oil is the right one for lubing the rest of my lathe alongside my way oil, any suggestions ?

Lately, I have been noticing that my lathe vibrates excessively at 1000 RPM. That's normal ?

I am not sure if the ISO 10 oil is the right one for lubing the rest of my lathe alongside my way oil, any suggestions ?

Lately, I have been noticing that my lathe vibrates excessively at 1000 RPM. That's normal ?