- Joined

- Feb 8, 2014

- Messages

- 11,144

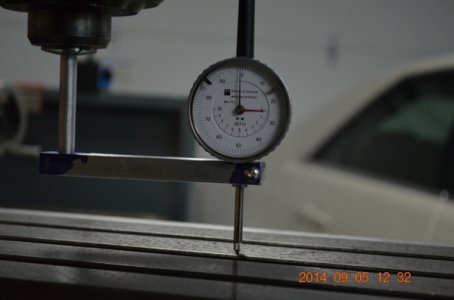

Nice job on the indicator holder, looks good. You are doing it just like I do. The only thing I do different is turn the indicator 90* counterclockwise from your position, so you don't have to use a mirror in the rear. I normally set the nod first, then do the tilt.

I would say if the result is what you want, then you did it correctly.

I would say if the result is what you want, then you did it correctly.