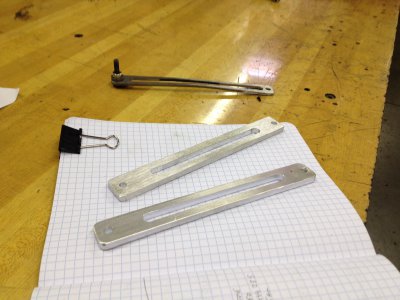

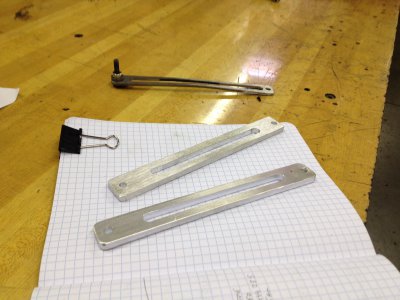

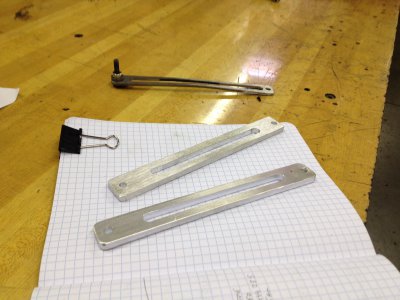

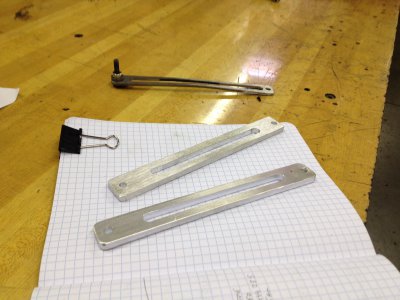

Here are the parts in question. I made the first one from 7GA steel, you see that at the very top of the picture. My dimensions were far from accurate on this one, but it allowed me to get my machine running to fine tune everything. The one on the middle of the first picture was made from 1/4" aluminum and turned out pretty nice. The one at the bottom of the first picture is a laser cut example of the same thing. I didn't know our in-house fabrication shop would be able to get to it as soon as they did, so I made my own while I was waiting.

This picture shows the same aluminum parts as the picture above with the laser cut part being on the left.

So what do these things do? Well, here are some pics of the final project. I work for a company which makes bowling equipment. A lower dollar version of a pinspotter is a string pinspotter. They use regular bowling pins, but they have a hole in the top to allow the string to attach and a bushing which flexes. I'm trying to test the longevity of the bushing. I built the entire machine so it used an electric motor stepped down to lower speed twice (motor speed 1700 rpm, lower pulley speed 70 rpm) with the pulley ratios. The slotted arms pivot at the top and the slot rides in a pin that goes around on the pulley. The string from the pin is tied around the lower hole in the slotted arm. This provides a quick yank of the string as it goes around and then relaxes more gradually. You can see the bottom of the swing arms in the last picture where the bushings are in the relaxed state.

This picture shows the same aluminum parts as the picture above with the laser cut part being on the left.

So what do these things do? Well, here are some pics of the final project. I work for a company which makes bowling equipment. A lower dollar version of a pinspotter is a string pinspotter. They use regular bowling pins, but they have a hole in the top to allow the string to attach and a bushing which flexes. I'm trying to test the longevity of the bushing. I built the entire machine so it used an electric motor stepped down to lower speed twice (motor speed 1700 rpm, lower pulley speed 70 rpm) with the pulley ratios. The slotted arms pivot at the top and the slot rides in a pin that goes around on the pulley. The string from the pin is tied around the lower hole in the slotted arm. This provides a quick yank of the string as it goes around and then relaxes more gradually. You can see the bottom of the swing arms in the last picture where the bushings are in the relaxed state.