A few years ago I got a precision Matthews pm30mv benchtop mill and got a 5" vise from them with it. I was having issues with the fixed jaw moving I think because if I clamped something closer to the top of the Jaws the piece would lift off the parallels quite a bit. So I took everything all apart and cleaned it up and got better bolts and when torquing them down the jaw split out since the holes are so close to the edge, it didn't even hit 50ftlbs of torque and those are m10 bolts. So I'm thinking it's just time to upgrade to something nice that won't have these problems. I can't afford Kurt so looking for something that's better quality than the $150 vise that I got with the machine but not Kurt price. I've heard of glacern but that's about all. What would you recommend? I also know that there are plenty of other threads on this but most of them are a few years old and prices and brands and models change so looking for current stuff. Also wondering if I should step down to a 4" vise. The table is 8x33 and with the 5" I lost a bit of y travel.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New vise recommendation

- Thread starter Lee250

- Start date

- Joined

- Apr 14, 2014

- Messages

- 3,152

For my vertical mill I have an 8" Palmgren, and a 6" Bridgeport. Both are accurate, but the Palmgren is easier to setup. Looking at the price of a Palmgren it appears they're in the same price range as the Kurts.

I took a chance on a 4" Chicom (Vevor) vise for my horizontal mill. It was a $70.00 cheapie, so I didn't expect much. As it turned out it's accurate within a few tenths. I was holding my breath thinking it could be a disaster. If it had been inaccurate, it would have cost as much to return it as the vise itself cost. If you live near a distributor that handles these types of vises, and they allow in person pickup it might be worth the chance. If it doesn't work out, you can return it in person and avoid the shipping charges.

I took a chance on a 4" Chicom (Vevor) vise for my horizontal mill. It was a $70.00 cheapie, so I didn't expect much. As it turned out it's accurate within a few tenths. I was holding my breath thinking it could be a disaster. If it had been inaccurate, it would have cost as much to return it as the vise itself cost. If you live near a distributor that handles these types of vises, and they allow in person pickup it might be worth the chance. If it doesn't work out, you can return it in person and avoid the shipping charges.

- Joined

- Jul 29, 2014

- Messages

- 2,737

I have an import 6” with swivel (that I like and use occasionally). It’s passed every accuracy test I’ve checked in good order…the only thing I don’t like so much is it’s limited to slightly more than a 6” opening, and I’m envious of the 9” capability of the more expensive vises.

Yeah my 5" only opened a little more than 5" and the swivel base was handy as well. More of my problem may have been how tight I clamp things that was probably why the jaw was moving. I think as long as whatever I get doesn't have the holes so close to the edge of the jaw it would be stronger.I have an import 6” with swivel (that I like and use occasionally). It’s passed every accuracy test I’ve checked in good order…the only thing I don’t like so much is it’s limited to slightly more than a 6” opening, and I’m envious of the 9” capability of the more expensive vises.

- Joined

- Oct 31, 2016

- Messages

- 2,645

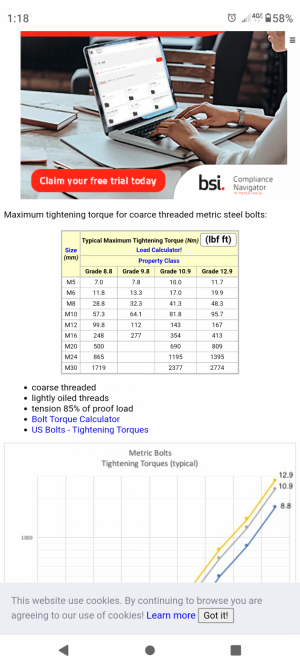

I think that one cause of the cracks may be over tightening the 10m bolt. Is it a socket head? 50 ft lbs of torque exceeds the specs for a 10m bolt except for the highest grade 12.9 bolts. Even then the jaw shouldn't crack. I would check how flat the vise is where the jaw rests against the vise and how flat the jaw is.

IMHO a 5" vise is slightly over size for your mill. A 4" vise would be a better fit.

I think Joe Pi has a video on what causes the work to lift off of a parallel.

IMHO a 5" vise is slightly over size for your mill. A 4" vise would be a better fit.

I think Joe Pi has a video on what causes the work to lift off of a parallel.

I went with this chart for the torque spec. I got new 12.9 bolts to put in it but before 50 ftlbs it went already. Joe pi does good videos and I will have to find that one. I was also thinking the 5 was a little big for my mill which is why I figured a 4 would work better. Thanks for the input.

Attachments

- Joined

- Oct 31, 2016

- Messages

- 2,645

I saw that page too. To get the torque in ft lbs you needed to click on the lbf ft box in the upper right corner. I looked at several other pages too and those pages listed the torque for a 10mm bolt at lower numbers.

- Joined

- Jan 4, 2021

- Messages

- 1,792

@Lee250

I have been very pleased with my 3" Heavy Precision Milling Vise that I got from Little Machine Shop when I purchased my Mini-Mill ($140 with swivel base currently). while it is not a Kurt, it does have a Kurt-style hold-down mechanism and while the jaws only open to 3", I can hold work up to 8" by moving the jaws. I also made a set of 1-1/2" tall jaws from precision ground low carbon bar, so the vise probably can outperform the mill.

LMS also has a 4" version of this vise for $155; all of the Kurt 4" accessories should fit. From what I have read, a 4" vise is better suited to your mill, even though a 5" will "fit."

I have been very pleased with my 3" Heavy Precision Milling Vise that I got from Little Machine Shop when I purchased my Mini-Mill ($140 with swivel base currently). while it is not a Kurt, it does have a Kurt-style hold-down mechanism and while the jaws only open to 3", I can hold work up to 8" by moving the jaws. I also made a set of 1-1/2" tall jaws from precision ground low carbon bar, so the vise probably can outperform the mill.

LMS also has a 4" version of this vise for $155; all of the Kurt 4" accessories should fit. From what I have read, a 4" vise is better suited to your mill, even though a 5" will "fit."