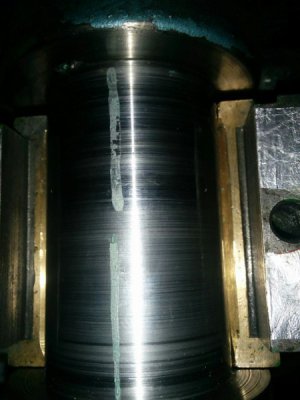

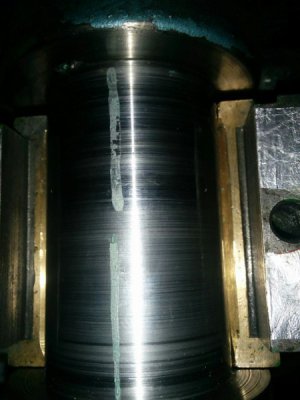

So I got a chance to try out some thinner shims I got the oil clearance to about .0015 on half of the bearing.... I think the plastigage is trying to tell me a story lol

it tapers down to a .003 gap about a 1/2" from the end of the bearing this is the side closest to the chuck. Is this OK? I mean I'm gonna have to run what I've got but what kind of problems if any will I get from this? And is there any remedy for this?

it tapers down to a .003 gap about a 1/2" from the end of the bearing this is the side closest to the chuck. Is this OK? I mean I'm gonna have to run what I've got but what kind of problems if any will I get from this? And is there any remedy for this?