hey guys i just got me a used little 9x19 and would like to know where is the best place for me to find/buy some tooling for it in the kelowna area? i am a total noob on this lathe but want to learn as much as i can with it thanx

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

new to me grizzly g4000 9x19 need tooling??

- Thread starter dasboat

- Start date

Have you considered what type tooling you want? Carbide inserts? HSS bits? Grizzly has a 7 piece carbide set that will work on that lathe. Comes with 1 set of inserts and replacement inserts can be had at places like Shar's or ebay for a good price. Enco has 15% off through today, don't know how shipping works to BC from Nevada, USA. They have a good selection of square and round HSS tool bits you can use to make your own. You can apparently find lots of used HSS bits on ebay that you can regrind.

Dave

Dave

thanx i have not thought about what parts i need yet i just wanted some common ones to get me started to play with until i get it figured out. i have looked at grizzly at these but not sure they are any good? G9776 Carbide-Tipped Tool Bit Sets - 3/8" 20 pc and for 23 bucks plus the ride i thought they might get me started?

- Joined

- Dec 18, 2013

- Messages

- 2,012

I outgrew the brazed on carbide tools in about 2 weeks. I researched tooling heavily for my G4003G and here's what I ended up getting...

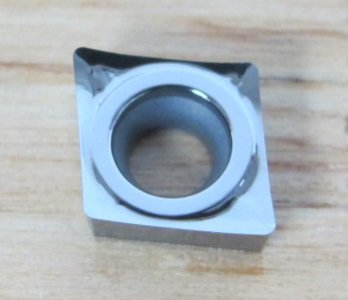

Glanze Turning Set 1/2" shank - I found a number of people recommending this tool set, not sure what size shank tools your lathe takes but Grizzly has a smaller shank set as well. Imported from India. http://www.grizzly.com/products/Glanze-Turning-Tool-Set-1-2/H5681 These all use the same insert, CCMT and CCGT its a pretty common insert and not overly expensive. CCMT for steel, CCGT for aluminum, brass, plastic, wood. The Kolroy CCGT carbide inserts are polished and razor sharp. I saw a recommendation for Kolroy brand inserts and purchased a box of 10 CCGT's from US Shop Tools in California. So far they work very nice. There are different sizes in CCMT/CCGT you want the 21.51 e.g. CCGT21.51

Glanze Parting Tool - you can spent a LOT more for this type of parting tool but I saw no reason to upgrade. For $99 you get the tool holder, two blades, 4 inserts I couldn't find a deal that came close to that anywhere. Grizzly shows some silver coating FAIL it was blued dark steel which suited me fine I don't like the silver coating. The 4 inserts that come with it are neutral and more suited for steel. It uses the common GTN3, GTR3, GTL3 (N-neutral, R-right, L-left) for the wider blade, I think the narrow blade is GT_2. I ordered a box of GTR3 Newcomer brand, US Shop Tools was out of the Dorian inserts. Specifically CI-218 C2 which are the C2 grade uncoated for aluminum and brass.

Boring Bars - I cheaped out here and went with the Grizzly set http://www.grizzly.com/products/Carbide-Insert-CCMT-Boring-Bar-Set-3-pc-/T10438 this uses the same CCMT/CCGT inserts as the Glanze tooling above. I figure if I'm going to get into trouble and wipe out a tool its probably going to be boring so rather that blow big dollars on boring bars I'll practice with these. They seem perfectly fine quality wise. The strategy here was to try to limit the different types of inserts as they are expensive. So both my turning tools and boring bars use the same insert.

For threading I went with Carmex tool holders and laydown inserts. These were widely recommended in my research. I purchased these external and internal Carmex tool holders from US Shop Tools T-CMSER0625H16 $82.50, T-CMSIR0500M16B $105.42 then found them cheaper elsewhere (face palm) the internal is plumbed for through coolant, the non-coolant version is much cheaper. I went with these threading inserts for starters. There is a maddening volume of threading inserts, a bunch specific to a particular thread pitch, others like these below that can turn a range of threads, then there's like 3-4 different sizes these below are 16's there's also 11's and some others similar to the CCMT/CCGT inserts above coming in different sizes.

T-C16ERAG60K2 $11.43 (they sent me the wrong insert, should have been K2 uncoated it was coated)

T-C16IRAG60K2 $12.95 (they were out of stock)

T-C16ERAG60M2 $12.95

T-C16IRAG60M2 $12.95

Tooling FAIL to avoid

The Grizzly parting tool holder blows ass, I started with the HHS parting blade and their recommended tool holder, the parting blade is beveled top and bottom, the tool holder is flat and the blade won't lock in place properly :angryfire:

CHINA tool holders, about every other one is poorly made. Tapped crooked, loose height stud threads. I'm done buying any more and will go Dorian tool post and tool holders from here on out.

Glanze Turning Set 1/2" shank - I found a number of people recommending this tool set, not sure what size shank tools your lathe takes but Grizzly has a smaller shank set as well. Imported from India. http://www.grizzly.com/products/Glanze-Turning-Tool-Set-1-2/H5681 These all use the same insert, CCMT and CCGT its a pretty common insert and not overly expensive. CCMT for steel, CCGT for aluminum, brass, plastic, wood. The Kolroy CCGT carbide inserts are polished and razor sharp. I saw a recommendation for Kolroy brand inserts and purchased a box of 10 CCGT's from US Shop Tools in California. So far they work very nice. There are different sizes in CCMT/CCGT you want the 21.51 e.g. CCGT21.51

Glanze Parting Tool - you can spent a LOT more for this type of parting tool but I saw no reason to upgrade. For $99 you get the tool holder, two blades, 4 inserts I couldn't find a deal that came close to that anywhere. Grizzly shows some silver coating FAIL it was blued dark steel which suited me fine I don't like the silver coating. The 4 inserts that come with it are neutral and more suited for steel. It uses the common GTN3, GTR3, GTL3 (N-neutral, R-right, L-left) for the wider blade, I think the narrow blade is GT_2. I ordered a box of GTR3 Newcomer brand, US Shop Tools was out of the Dorian inserts. Specifically CI-218 C2 which are the C2 grade uncoated for aluminum and brass.

Boring Bars - I cheaped out here and went with the Grizzly set http://www.grizzly.com/products/Carbide-Insert-CCMT-Boring-Bar-Set-3-pc-/T10438 this uses the same CCMT/CCGT inserts as the Glanze tooling above. I figure if I'm going to get into trouble and wipe out a tool its probably going to be boring so rather that blow big dollars on boring bars I'll practice with these. They seem perfectly fine quality wise. The strategy here was to try to limit the different types of inserts as they are expensive. So both my turning tools and boring bars use the same insert.

For threading I went with Carmex tool holders and laydown inserts. These were widely recommended in my research. I purchased these external and internal Carmex tool holders from US Shop Tools T-CMSER0625H16 $82.50, T-CMSIR0500M16B $105.42 then found them cheaper elsewhere (face palm) the internal is plumbed for through coolant, the non-coolant version is much cheaper. I went with these threading inserts for starters. There is a maddening volume of threading inserts, a bunch specific to a particular thread pitch, others like these below that can turn a range of threads, then there's like 3-4 different sizes these below are 16's there's also 11's and some others similar to the CCMT/CCGT inserts above coming in different sizes.

T-C16ERAG60K2 $11.43 (they sent me the wrong insert, should have been K2 uncoated it was coated)

T-C16IRAG60K2 $12.95 (they were out of stock)

T-C16ERAG60M2 $12.95

T-C16IRAG60M2 $12.95

Tooling FAIL to avoid

The Grizzly parting tool holder blows ass, I started with the HHS parting blade and their recommended tool holder, the parting blade is beveled top and bottom, the tool holder is flat and the blade won't lock in place properly :angryfire:

CHINA tool holders, about every other one is poorly made. Tapped crooked, loose height stud threads. I'm done buying any more and will go Dorian tool post and tool holders from here on out.

Thanx . o boy do i got some reading to do now. i forgot to say my holder will hold the 1/2" bits

has anyone tried the magnum cutters from kms or are they junk ? like these http://www.kmstools.com/magnum-9pc-metal-lathe-cutter-set-20601

they are local to me

has anyone tried the magnum cutters from kms or are they junk ? like these http://www.kmstools.com/magnum-9pc-metal-lathe-cutter-set-20601

they are local to me

Last edited:

- Joined

- Mar 31, 2014

- Messages

- 607

Though carbide tooling is wonderful I'd recommend about 10 pieces of High Speed steel to get started with, do a search for Grinding HSS lathe tools and give it try, even if you do eventually go to carbide tooling there will be times you'll need a special form tool or a certain shape tool that's not worth purchasing in carbide for the little it's used, after grinding a few tools and doing a little experimenting you'll have a good idea what shape of carbide holders would be most useful to you for the type of things your machining, and when you do need to have a go at that special form tool you'll have gained some experience in grinding HHS tools and a better understanding of the rake, clearances and such needed, I'd recommend not to go for the cheapest in HSS, not all HSS is created equally, for instance we have Busy Bee here in Canada and I've found the few HSS bits I've purchased from them have been hit and miss, they'll get the job done but by times they just require to much regrinding to get through a job ( won't hold there edge ) try to find a local dealer if possible that supplies machine shops, the price per piece won't be that much more.

Any high Speed steel you buy now to experiment with can always be reground latter for those special jobs, they'll not go to wast. )

)

Any high Speed steel you buy now to experiment with can always be reground latter for those special jobs, they'll not go to wast.