- Joined

- Mar 12, 2021

- Messages

- 63

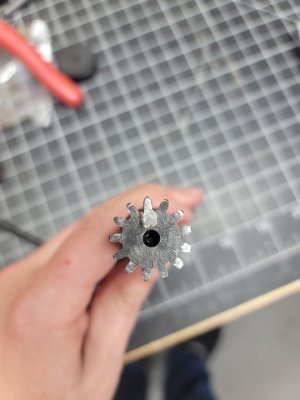

build/restoration process slowed/halted by the broken gear or gearshaft in the apron, and debating how to transit it into the basement before winter (and being partially apart may help that.

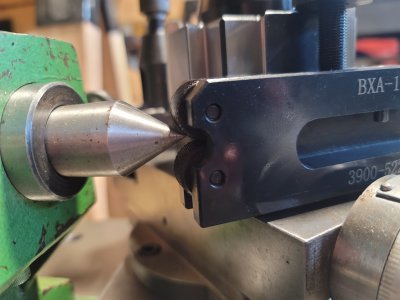

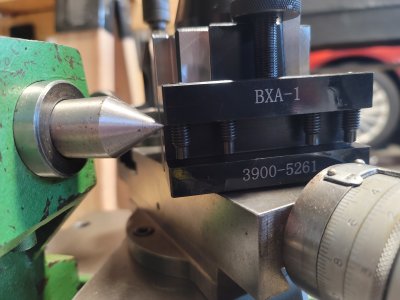

But being a wild and brash individual I had a nice coupon that would let me pick up a quick change tool post pretty reasonable, from sizing guides BXA covered 12 in swing and thats what i got so bigger = beefier = more stable right. and that's what I went with. I couldn't find detailed specs on tool heights but i decided grab it and see.

so figured the knurling attachment would be easy to see as it has the tool baked into it. tool mount is not bottomed out on the compound and nearly as low as it can go and it sits below center point think we are good?

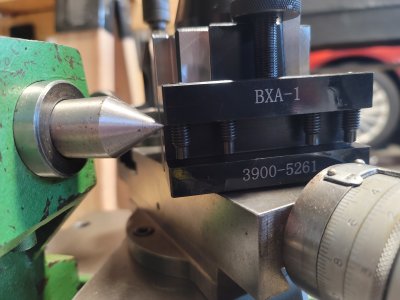

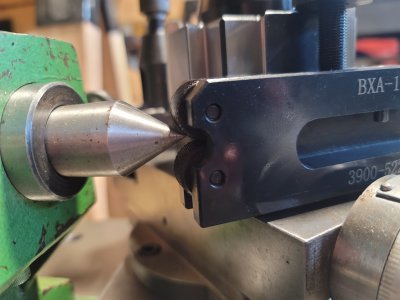

took a normal tool holder out and dropped that in as well once again nearly bottoming it out on he compound (ignore the fact its spun around ) and the top edge of the tool holder just below center/at center

overall the tool post is almost as wide as the compound. the question is while its still "new" did I do a dumb or should i return it for a AXA?

I think though optimally you want the tool as low on the post as you can as its the most rigid right? just want to make sure i have the right sizing to fit or use with my machine.

But being a wild and brash individual I had a nice coupon that would let me pick up a quick change tool post pretty reasonable, from sizing guides BXA covered 12 in swing and thats what i got so bigger = beefier = more stable right. and that's what I went with. I couldn't find detailed specs on tool heights but i decided grab it and see.

so figured the knurling attachment would be easy to see as it has the tool baked into it. tool mount is not bottomed out on the compound and nearly as low as it can go and it sits below center point think we are good?

took a normal tool holder out and dropped that in as well once again nearly bottoming it out on he compound (ignore the fact its spun around ) and the top edge of the tool holder just below center/at center

overall the tool post is almost as wide as the compound. the question is while its still "new" did I do a dumb or should i return it for a AXA?

I think though optimally you want the tool as low on the post as you can as its the most rigid right? just want to make sure i have the right sizing to fit or use with my machine.