I do not know year , am hoping someone here knows. you say yours a 71 , to me that’s pretty new. I hope mine is that age I assumed 50s or 60sThat is a different motor mount / countershaft setup than on my 10K.

This is the only picture I have on the computer, but could take more if you want to see it in better detail.

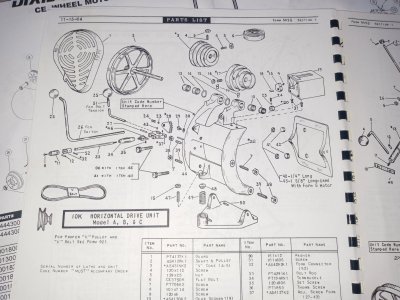

Mine is also a CL670Z and it looks like the horizontal drive setups shown in the brochures.

Do you know what year your lathe is? I think mine was 1971 give or take a year.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New to me 10K , drive questions

- Thread starter Sandbox

- Start date

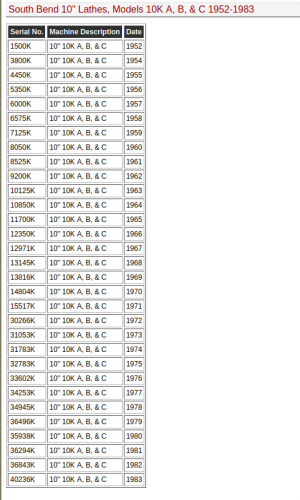

Thank you piper , just what I hoped to find out. I figured a 4 digit serial was pretty old as I’d see 5 digit ones. My lathe 1961. Good to know thank you very much I will save the list.

This is a better pic of the distance and the part over hang back , and is on 1+1/4” high box . I got the table with the lathe and believe they have been together quite a while.

This lathe had a three phase motor and the speed controller thing that takes 240 volts 1 phase and somehow runs 3 phase motor. I had a 120v 3/4hp 1 phase 1725rpm motor here and have put it on this now. Plain vanilla good enough for me. I saved the speed controller and motor. To left on wall is water line hurricane Irma.

This is a better pic of the distance and the part over hang back , and is on 1+1/4” high box . I got the table with the lathe and believe they have been together quite a while.

This lathe had a three phase motor and the speed controller thing that takes 240 volts 1 phase and somehow runs 3 phase motor. I had a 120v 3/4hp 1 phase 1725rpm motor here and have put it on this now. Plain vanilla good enough for me. I saved the speed controller and motor. To left on wall is water line hurricane Irma.

Last edited:

- Joined

- Jan 20, 2018

- Messages

- 5,638

I just sand down to the cord on each end. No taper, just a flat lap. Just don't damage the cord. The splice ends up a little thicker than the belt.Mr Whoopee ! ***. You are the man I want.

I just bought a new tube of Shoe Goo to fix my sneakers the day before I got this lathe.

I don’t understand how to taper the smooth side of serpentine belt. Easy to grind ribbed side, the cord is on smooth side.

Do you sand the back of the belt? Grind ribs off both ends glue overlap clamp. Thanks for getting back to me.I just sand down to the cord on each end. No taper, just a flat lap. Just don't damage the cord. The splice ends up a little thicker than the belt.

Last edited:

- Joined

- Jan 20, 2018

- Messages

- 5,638

Sand the back on one end, the ribs on the other.Do you sand the back of the belt? Grind ribs off both ends glue overlap clamp. Thanks for getting back to me.

That is definitely not the same drive setup as I have or seen in the documents I downloaded which were dated 1966.

It might be that someone adapted a motor and countershaft from another lathe, hence the riser block.

Here are a couple of links that will take you down a rabbit hole of information

All kinds of info out there, from belt splicing to original catalogs

Save that 3 phase motor and VFD. There will be a time when you want it on the lathe again so you have infinite speed control.

Enjoy

It might be that someone adapted a motor and countershaft from another lathe, hence the riser block.

Here are a couple of links that will take you down a rabbit hole of information

All kinds of info out there, from belt splicing to original catalogs

Save that 3 phase motor and VFD. There will be a time when you want it on the lathe again so you have infinite speed control.

Enjoy

Thank you , I have a old serp belt to cut up I’m going to try some practice joint.Sand the back on one end, the ribs on the other.

Thanks, the book I got with the lathe shows both this countershaft with 10k, and yours is on page before this. The VFD would complicate getting lathe up n running ,240 volt, and I would have to learn something new. I looked at the book for VFD and reminded me of trying to set a VCR , remember those?That is definitely not the same drive setup as I have or seen in the documents I downloaded which were dated 1966.

It might be that someone adapted a motor and countershaft from another lathe, hence the riser block.

Here are a couple of links that will take you down a rabbit hole of information

All kinds of info out there, from belt splicing to original catalogs

Save that 3 phase motor and VFD. There will be a time when you want it on the lathe again so you have infinite speed control.

Enjoy

Vintage Machine has a 1951 10K new first intro pamphlet 8 pages. The countershaft was “Close Coupled“ was one bragging point. It sat only couple inches behind headstock.

Last edited: