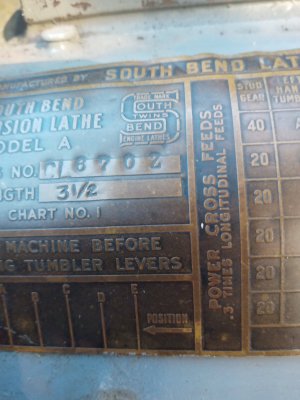

I just received a South Bend lathe, I’m getting it set up and I want to move the countershaft/motor closer to the lathe.

The lathe assembly over 3 feet wide now , the table is 22 inch wide and countershaft base overhangs back several inch. I want to move it so no over hang and base will be inch lower, belt too close bottom run if on large countershaft drum.

The lathe assembly over 3 feet wide now , the table is 22 inch wide and countershaft base overhangs back several inch. I want to move it so no over hang and base will be inch lower, belt too close bottom run if on large countershaft drum.

Attachments

Last edited: