- Joined

- Dec 10, 2011

- Messages

- 3

Hey fellas,

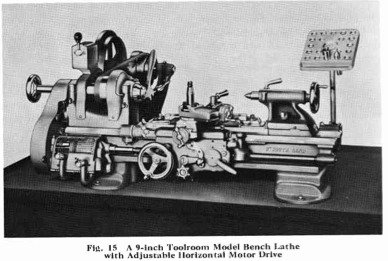

Picked up a south bend lathe 9. It has 3 belt locations, with the pull pin style back gear, and a 3 phase motor running a 2 speed pulley setup. Got everything hooked up and works so far. I have cutting tools on order.

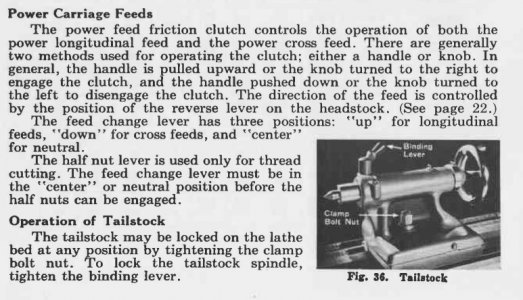

So I have read the 1966 version of "how to run a lathe". I am slightly confused with the apron controls. My apron looks exactly like the one in the picture on the left. I understand the longitudinal, cross and compound handles and way they do... Can someone explain what the clutch knob, feed control lever, and half nut lever do? When I turn my lathe on, the feed screw is turing, and I can raise the half nut lever and get the longitudinal feed to work. The manual says that is for threading only. So what does the feed control lever and clutch knob do?

The manual says the clutch controls power feeds, but engaging the half nut lever appears makes the apron move left and right. Do both the clutch knob and half nut lever do the same thing? How do I engage the cross power feed? I can't see anywhere that explains the feed control lever and its purpose... Anyways, basically just looking for the down and dirty on what each lever/knob does and when to use it for what. Thanks guys...

Picked up a south bend lathe 9. It has 3 belt locations, with the pull pin style back gear, and a 3 phase motor running a 2 speed pulley setup. Got everything hooked up and works so far. I have cutting tools on order.

So I have read the 1966 version of "how to run a lathe". I am slightly confused with the apron controls. My apron looks exactly like the one in the picture on the left. I understand the longitudinal, cross and compound handles and way they do... Can someone explain what the clutch knob, feed control lever, and half nut lever do? When I turn my lathe on, the feed screw is turing, and I can raise the half nut lever and get the longitudinal feed to work. The manual says that is for threading only. So what does the feed control lever and clutch knob do?

The manual says the clutch controls power feeds, but engaging the half nut lever appears makes the apron move left and right. Do both the clutch knob and half nut lever do the same thing? How do I engage the cross power feed? I can't see anywhere that explains the feed control lever and its purpose... Anyways, basically just looking for the down and dirty on what each lever/knob does and when to use it for what. Thanks guys...