I see by the forum rules that I need to have 3 posts before I can search the site for things of interest, so here goes post #1.

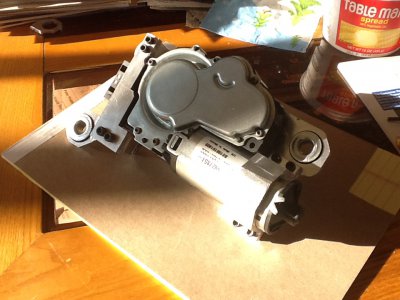

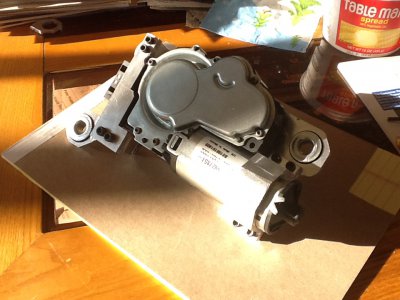

My rear wiper assy on an 11 yr old BMW X5 “fell off” inside the tailgate one day. I took it apart and wondered who thought it was a good idea to mount a several pound unit to a hatch-back with silly little plastic tabs molded into the housing. A replacement unit is a couple hundred bucks (German parts!), but there was absolutely nothing wrong with the functionality of the one I have. I just needed to come up with a more durable mounting system.

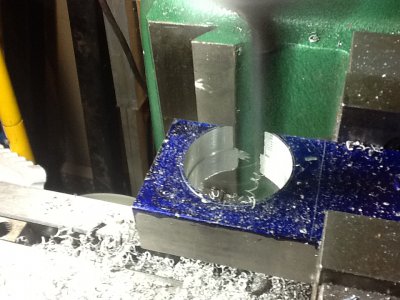

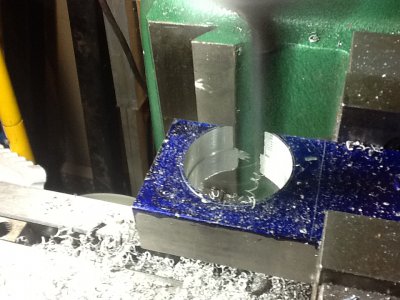

So, after a few hours doodling and making some chips in the garage, here we go (eventually I may get the hang of in-line pictures with individual descriptions, but I think the series of selected pictures tells the story):

My rear wiper assy on an 11 yr old BMW X5 “fell off” inside the tailgate one day. I took it apart and wondered who thought it was a good idea to mount a several pound unit to a hatch-back with silly little plastic tabs molded into the housing. A replacement unit is a couple hundred bucks (German parts!), but there was absolutely nothing wrong with the functionality of the one I have. I just needed to come up with a more durable mounting system.

So, after a few hours doodling and making some chips in the garage, here we go (eventually I may get the hang of in-line pictures with individual descriptions, but I think the series of selected pictures tells the story):