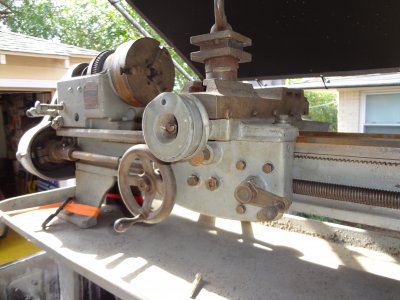

Here is my before and after of my first lathe: Purchased a 1945 non running South Bend 9A ($400) with 7 missing teeth on the bull gear and zero teeth of the backgear and a worn worm gear that made the power feed slip. Total cost to repair - about 100 hours of sweat equity and $18 which was the price of a used worm gear. I made/repaired the other gears from scrap material. No prior experience, all info gathered browsing forums like this.