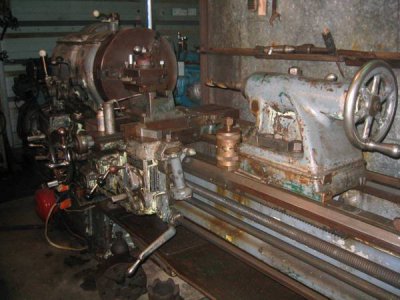

So here's the machine I'm going to check out this Saturday:

http://goldcountry.craigslist.org/tls/4579039915.html

I'm pretty unfamiliar with lathes. Have done metal fabrication just about my whole life, but never had access to a lathe. I build off road vehicles as a hobby/side work, desert race/rock crawlers specifically. Since I'm very novice at the moment, I'll have an immediate use for the machine making bearing drivers, maybe an odd bushing here and there, various tools (would love to make a carrier bearing puller), auto transmission clutch pistons (to add frictions), etc. As I get more experience, I'll probably start polishing crankshafts and possibly fabricating axle housings and steering components.

I'd like to know anyone's comments on this machine, the asking price, things to look out for, etc. From my research, it sounds like I should investigate for damaged gears and wear on the ways. The guy said he'd send me the serial later, so I've been trying unsuccessfully to identify the model from the pictures. Along with researching the machine more in-depth, I'd like to get the model number so I could better approximate a weight. I'm guessing around 3-4k lbs. I'm going to pick it up with my k1500 and 7k lbs car hauler, so I'd like to make sure I don't need to borrow a diesel and a bigger trailer before I try to drag it up Donner Pass in July.

http://goldcountry.craigslist.org/tls/4579039915.html

I'm pretty unfamiliar with lathes. Have done metal fabrication just about my whole life, but never had access to a lathe. I build off road vehicles as a hobby/side work, desert race/rock crawlers specifically. Since I'm very novice at the moment, I'll have an immediate use for the machine making bearing drivers, maybe an odd bushing here and there, various tools (would love to make a carrier bearing puller), auto transmission clutch pistons (to add frictions), etc. As I get more experience, I'll probably start polishing crankshafts and possibly fabricating axle housings and steering components.

I'd like to know anyone's comments on this machine, the asking price, things to look out for, etc. From my research, it sounds like I should investigate for damaged gears and wear on the ways. The guy said he'd send me the serial later, so I've been trying unsuccessfully to identify the model from the pictures. Along with researching the machine more in-depth, I'd like to get the model number so I could better approximate a weight. I'm guessing around 3-4k lbs. I'm going to pick it up with my k1500 and 7k lbs car hauler, so I'd like to make sure I don't need to borrow a diesel and a bigger trailer before I try to drag it up Donner Pass in July.

Last edited: