- Joined

- Aug 13, 2020

- Messages

- 1,342

I posted pictures of my purchase(s) here: https://www.hobby-machinist.com/threads/what-did-you-buy-today.55645/post-988358

When I jump in , I tend to jump in headfirst. The point I'm at now, I've bought a Bridgeport clone whose head appears to be a basket case, and a head off a different clone that is quite different. I also need a way to power the 3phase motors.

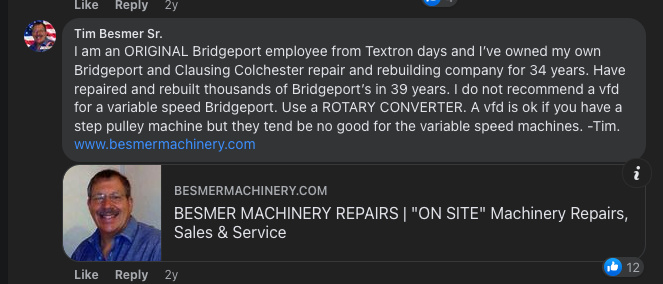

I think I've settled on a VFD to get 3phase. VFDs are cheap, and I only have the one machine to power. RPCs seem to be noisy power hogs, and SPCs cost as much as VFDs, but force you to give up 1/3rd of the power.

The head that is on the machine is a varispeed, but seems to be missing the worm gear. The other head is a belt swapping model. Would it be better to fix the varispeed and lock the VFD to 60Hz? Or simplify things with the belt swapper, and control speed with the VFD?

When I jump in , I tend to jump in headfirst. The point I'm at now, I've bought a Bridgeport clone whose head appears to be a basket case, and a head off a different clone that is quite different. I also need a way to power the 3phase motors.

I think I've settled on a VFD to get 3phase. VFDs are cheap, and I only have the one machine to power. RPCs seem to be noisy power hogs, and SPCs cost as much as VFDs, but force you to give up 1/3rd of the power.

The head that is on the machine is a varispeed, but seems to be missing the worm gear. The other head is a belt swapping model. Would it be better to fix the varispeed and lock the VFD to 60Hz? Or simplify things with the belt swapper, and control speed with the VFD?