- Joined

- May 10, 2012

- Messages

- 154

How do we save this post for future reference?

You could click on the "Watch" button to tag this conversation. Then later, click on the "Watched" button at the top of the page to find it amongst your watched topics.How do we save this post for future reference?

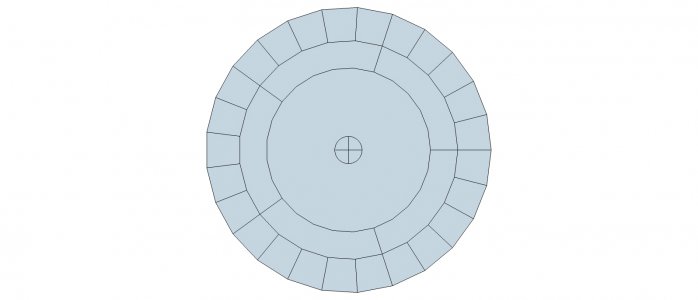

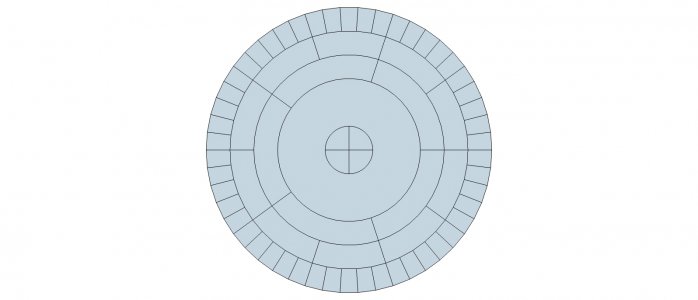

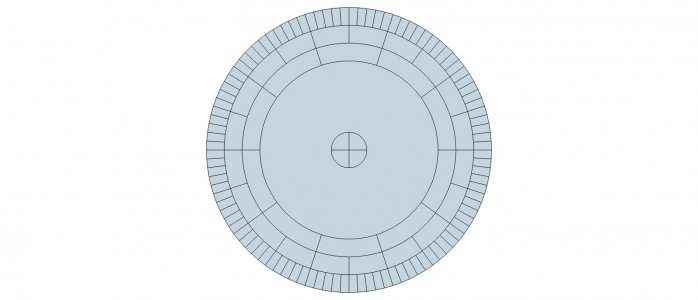

That is just so cool!!While I was in a dial making mood I thought I would make another one for the compound. I have an aftermarket steel compound because my stock cast iron one cracked. I had to make a new back plate with recessed bolts because of the size of the dial. These were easily the best mods I've done for my lathe, so nice to read the dials without magnification.