- Joined

- Mar 10, 2015

- Messages

- 309

Did some maint on my lathe over the weekend adjusted the clutch for carriage feed/ cross feed . Also installed a new cross feed nut .

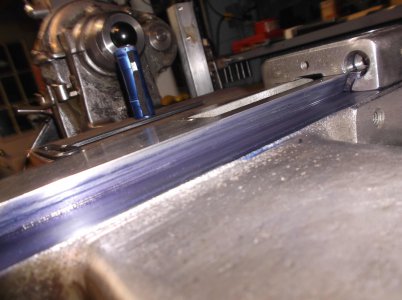

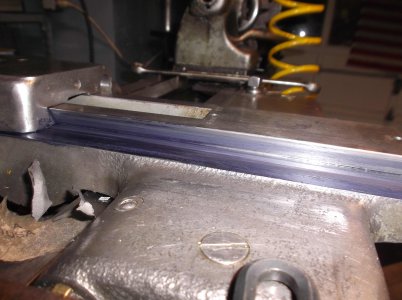

Had to do some cleaning up cross slide mating surfaces , and a bad spot on gib side surface. Well without going crazy taking off too much material i got er working smoothly with the new cross feed nut however bc of excess wear (i am guessing on the front side ) where the cross slide has been past 50 years. I was able to get cross slide to run nice and smooth without gib tight/ cross feed nut off.

However with gib properly adjusted she was not able to smoothly pass the centerline . Imo without stressing the new cross feed nut. She moves smoothly but is tight on the screw in that area . Any tips and tricks for repairing better without scraping all surfaces?

Gib Question ?

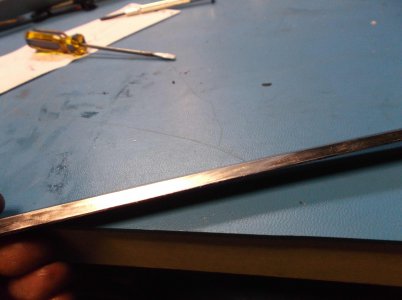

Ohh as far as Gib I did end up taking off material off to get her smooth. I used bluing and an oil stone. However i am at my last of last of gib adjustment now because i did remove all of the scaring . So now soon i may need a new gib to get a correct adjustment . For now needed to shim about .004 on the front side of the Gib for correct ajustemt .

Any ideas anything i can do altogether for the crosslide other than shimming ?

thanks in advance

Kenny V

Had to do some cleaning up cross slide mating surfaces , and a bad spot on gib side surface. Well without going crazy taking off too much material i got er working smoothly with the new cross feed nut however bc of excess wear (i am guessing on the front side ) where the cross slide has been past 50 years. I was able to get cross slide to run nice and smooth without gib tight/ cross feed nut off.

However with gib properly adjusted she was not able to smoothly pass the centerline . Imo without stressing the new cross feed nut. She moves smoothly but is tight on the screw in that area . Any tips and tricks for repairing better without scraping all surfaces?

Gib Question ?

Ohh as far as Gib I did end up taking off material off to get her smooth. I used bluing and an oil stone. However i am at my last of last of gib adjustment now because i did remove all of the scaring . So now soon i may need a new gib to get a correct adjustment . For now needed to shim about .004 on the front side of the Gib for correct ajustemt .

Any ideas anything i can do altogether for the crosslide other than shimming ?

thanks in advance

Kenny V