- Joined

- Feb 17, 2013

- Messages

- 314

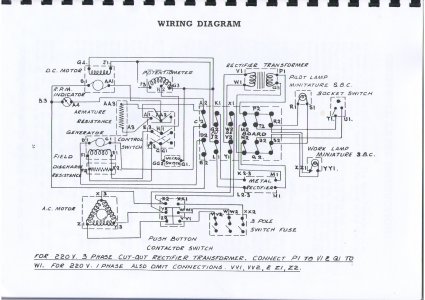

The lathe is suppose to be capable of 200 - 2000 in direct drive and 30 - 200 rpm in back gear. If there were other users around I could ask them, but it's a fairly rare lathe so I haven't heard from any other users. It does seem like a bit of a stretch for it to run at 170 V field and only 40 V armature voltage and still develop good torque at 200 rpm.

Michael

Michael