I picked up a Burke #4 mill last weekend. It came with an original vise (I think), and several dozen different sized milling cutters, and a mandrel. The milling cutters have three different sized I.D.'s, and the mandrel only fits the smallest. So, I'm going to be looking for a 1" mandrel, since most of my cutters are that size I.D.

Also included were several B&S #9 end mills with a tang. Can I use these in my spindle? I know there is no driver in the spindle, and no tapped hole in the end of the end mills for the draw bar.

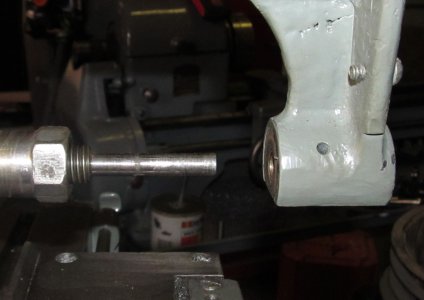

And I am including a picture from the Craigslist posting, because I know some of you think if there's no pictures, it didn't happen!

Also included were several B&S #9 end mills with a tang. Can I use these in my spindle? I know there is no driver in the spindle, and no tapped hole in the end of the end mills for the draw bar.

And I am including a picture from the Craigslist posting, because I know some of you think if there's no pictures, it didn't happen!