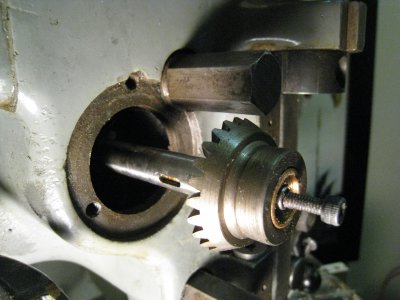

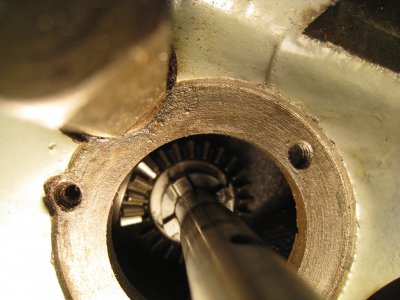

I recently purchased a series 1 mill - approx. 50 years young. The only issue was the fine downfeed with the hand wheel. I've tore it down and the problem hopefully is repaired. I am about to re-assemble but I need HELP with a few issues.

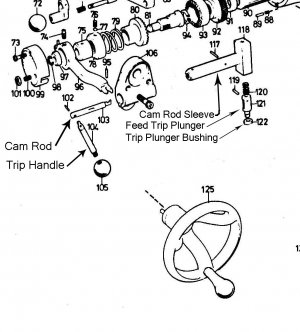

1.) In reassembling the trip mechanism / fine downfeed assembly - what lubricants are recommended? (for part#J-48/item# 103) cam rod, Ball on (part#J-49 / item#104), tryg Handle)

2) I was able to get the part#J-45 / item#121 (Trip Plunger) to move. There were fine chips lodged into the pin, at first I thought it was knurled! I have not been able to remove this pin. How is it removed? Is it pressed in?

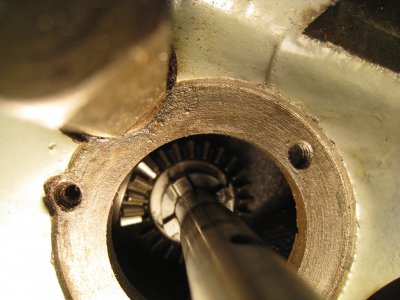

3) When I removed (part#J-110 / item# 49) the Feed Reverse Bevel Gear - there was no lubrication. Is this typically lubricated per manual by spindle oil on the "Quill Bearings" 3-10 drops twice daily?

I will try to attach pictures of the trip mechanism to help understand to what I am referring.

Any help would be appreciated! Thanks in advance.

1.) In reassembling the trip mechanism / fine downfeed assembly - what lubricants are recommended? (for part#J-48/item# 103) cam rod, Ball on (part#J-49 / item#104), tryg Handle)

2) I was able to get the part#J-45 / item#121 (Trip Plunger) to move. There were fine chips lodged into the pin, at first I thought it was knurled! I have not been able to remove this pin. How is it removed? Is it pressed in?

3) When I removed (part#J-110 / item# 49) the Feed Reverse Bevel Gear - there was no lubrication. Is this typically lubricated per manual by spindle oil on the "Quill Bearings" 3-10 drops twice daily?

I will try to attach pictures of the trip mechanism to help understand to what I am referring.

Any help would be appreciated! Thanks in advance.