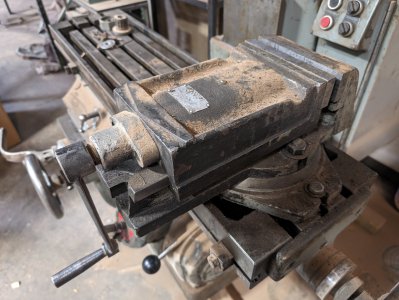

Hello there. Some of you may recognize this mill from my other thread for help with the purchase decision and initial research.

She's home and in my garage. I'll have lots of questions and I appreciate you all so much for already having been so helpful and encouraging with my lathe in the recent past, and now this mill.

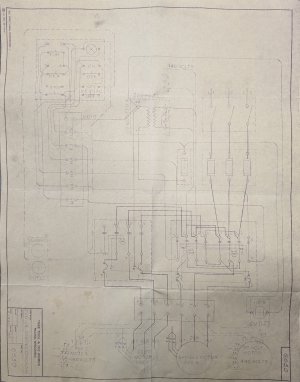

So I'll post a bunch of photos as an opener and would like to start by asking for help with identifying power requirements. My assumption was that this would need 3 phase 220v and I would purchase a RPC but I'm seeing on the schematic reference to 440v. Can someone help to clarify?

Thank you.

She's home and in my garage. I'll have lots of questions and I appreciate you all so much for already having been so helpful and encouraging with my lathe in the recent past, and now this mill.

So I'll post a bunch of photos as an opener and would like to start by asking for help with identifying power requirements. My assumption was that this would need 3 phase 220v and I would purchase a RPC but I'm seeing on the schematic reference to 440v. Can someone help to clarify?

Thank you.

Attachments

-

PXL_20240217_011921953.jpg345.8 KB · Views: 35

PXL_20240217_011921953.jpg345.8 KB · Views: 35 -

PXL_20240217_011907295.jpg398.9 KB · Views: 35

PXL_20240217_011907295.jpg398.9 KB · Views: 35 -

PXL_20240217_022052355.jpg332.5 KB · Views: 36

PXL_20240217_022052355.jpg332.5 KB · Views: 36 -

PXL_20240217_022134396~3.jpg293 KB · Views: 36

PXL_20240217_022134396~3.jpg293 KB · Views: 36 -

PXL_20240216_215126822.jpg920.3 KB · Views: 34

PXL_20240216_215126822.jpg920.3 KB · Views: 34 -

PXL_20240215_164501746.jpg331.1 KB · Views: 28

PXL_20240215_164501746.jpg331.1 KB · Views: 28 -

PXL_20240215_164452319.jpg295.1 KB · Views: 25

PXL_20240215_164452319.jpg295.1 KB · Views: 25 -

PXL_20240215_164901364.jpg502.3 KB · Views: 25

PXL_20240215_164901364.jpg502.3 KB · Views: 25 -

PXL_20240215_164859183.jpg360 KB · Views: 25

PXL_20240215_164859183.jpg360 KB · Views: 25 -

PXL_20240215_164852821.jpg450.4 KB · Views: 25

PXL_20240215_164852821.jpg450.4 KB · Views: 25 -

PXL_20240215_164841943.jpg429.3 KB · Views: 37

PXL_20240215_164841943.jpg429.3 KB · Views: 37