This will be my first adventure into internal threading. I need to purchase a tool for internal threads 3/4 x 16. I would like to be able to do as small as 1/2" . I prefer indexable carbide. My lathe (Asian 9 x 20) accepts 1/2' tooling. The toolpost will fit 0.750" but that would put me above center at the tool tip.

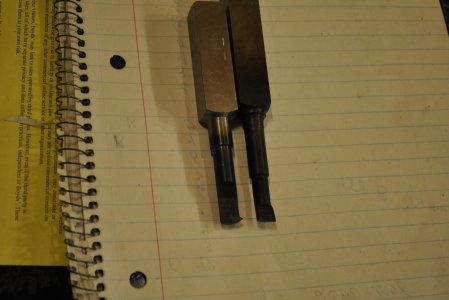

I was looking at something like this:

http://www.use-enco.com/CGI/INSRIT?PARTPG=INLMKD&PMPXNO=7908975&PMAKA=422-3038

The shank looks to be too large and would put my tool above center? I do not see any with 1/2" shanks? How are these tools typically held in the tool post? Any advice would be helpful.

Another thought. Should I just take a piece of 1/2" CRS and machine my own holder to fit that insert?

R

Carbide threading inserts are a possibility. They are available in a variety of shapes including the ones you found at Enco. Yes, you could make your own tool holder, but it depends on whether you have more time or more money. The carbide insert must be angled correctly to get the required rake angle, so the tool holder can take some time to fabricate.

Some single point carbide threading inserts are specified for one thread only (e.g. 16 TPI) and they will cut not only the vee sides of the thread, but also cut the inside diameter making a nice thread, but you need a different insert for each different pitch. Note they also make IR (internal) and ER (external) series inserts. Note that if you need a left hand thread, you may need a different insert, or perhaps use an ER series and rotate the part in reverse, cutting on the back-side of the bored hole for an inside thread. Many of the indexable ones have three cutting points and can be rotated when you wear out or damage one surface. There is also a series of inserts that will work for a range of pitches that do not cut the inside diameter of the hole, more like a vee thread; more versatile, but not quite as precise. It can be tricky getting the tool holder and insert to fit inside smaller diameter bores, so 1/2 inch diameter indexable insert may be pushing the limit. Multi-point threading inserts are also available. For smaller diameters, you probably are better off with a single point boring bar type tool. Little Machine Shop has a good selection, also check E-bay.

If you Google "inside threading lathe tools" and images, you will see a variety of shapes and styles.

The tool can be held in a boring bar holder for a QCTP or if square in a standard holder, just adjust the height to be on or very slightly above centerline of the part. Remember for inside cutting above centerline is good, for outside, a tiny bit below is good, since in both cases if the tool digs in and flexes, it pulls away from the surface rather than digging in deeper.