- Joined

- Dec 30, 2015

- Messages

- 131

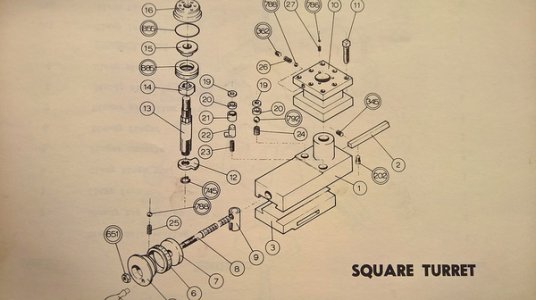

I have a series 57 Dumore tool post grinder that I picked up recently and also fixed up a bit. Now comes the task of mounting it to my lathe. The bore in the main housing of the Dumore is 1.5". My lathe has the original rotating tool holder with cam lever on top and four positions. You can see the style in the photo of the lathe. I tried taking it apart to see if by chance, the post was the right size but it's a bit larger at 1.75". It was a pain to take apart and worse to put back so I'm kind of glad that it didn't fit.

Anyone have any ideas on how to mount this thing? Maybe I have to remove the tool slide and build something that can bring it to the correct height.

On a side note, how do you put a QCTP on this lathe? Does it go right over the post that's in the middle of the original tool post?

Anyone have any ideas on how to mount this thing? Maybe I have to remove the tool slide and build something that can bring it to the correct height.

On a side note, how do you put a QCTP on this lathe? Does it go right over the post that's in the middle of the original tool post?