- Joined

- Mar 26, 2018

- Messages

- 8,408

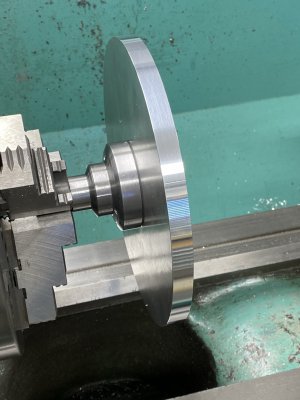

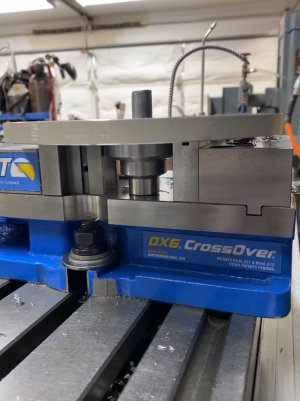

I am thrilled!

I haven’t been all that successful at making concentric arbors or attaching parts to motor shafts that didn’t have some run out.

This baby runs perfect.

I’ll make the pilot/register when the diamond lapping discs arrive.

I still need to drill and tap the flange And mill the magnet pockets.

To be honest, this part was giving me anxiety. I can move on to the frame and platen.

I haven’t been all that successful at making concentric arbors or attaching parts to motor shafts that didn’t have some run out.

This baby runs perfect.

I’ll make the pilot/register when the diamond lapping discs arrive.

I still need to drill and tap the flange And mill the magnet pockets.

To be honest, this part was giving me anxiety. I can move on to the frame and platen.

Attachments

-

87A841D8-ED73-4790-B0B8-439227273421.jpeg789.1 KB · Views: 114

87A841D8-ED73-4790-B0B8-439227273421.jpeg789.1 KB · Views: 114 -

C5E74F97-6489-4311-8BF5-FD7AA6F42EBC.jpeg783.1 KB · Views: 253

C5E74F97-6489-4311-8BF5-FD7AA6F42EBC.jpeg783.1 KB · Views: 253 -

7E1F6C0C-78C2-4563-B53F-B74E99C22813.jpeg571.3 KB · Views: 91

7E1F6C0C-78C2-4563-B53F-B74E99C22813.jpeg571.3 KB · Views: 91 -

B95EC03E-EC8C-4CB4-B2A4-F71DED660416.jpeg893.4 KB · Views: 94

B95EC03E-EC8C-4CB4-B2A4-F71DED660416.jpeg893.4 KB · Views: 94 -

7B2F79C9-6183-40B3-8DBF-B427FFFB4068.jpeg273.4 KB · Views: 99

7B2F79C9-6183-40B3-8DBF-B427FFFB4068.jpeg273.4 KB · Views: 99