There are gibb screws opposite each other that squeeze the quill to sort of prevent it from falling. They are located in the steel collar on top of the spindle stepped pulley.

There is supposed to be a spring under the screw and then a piece of brass that rides on the quill between the splines. You tighten them and put pressure on the quill that will sort of hold it up.

They both need to have the same tension or you can feel it in the down feed handle when the mill is running. It can be alarming when you feel all this intermiten resistance in the quill handle, but it's because you have one screw tighter than the other. It's a bit to fiddly, but if you get them both adjusted the same, the feeling almost completely goes away.

One of the 8520 sites talks about getting some springs out of I think .030 wire. I just did it and I don't think they are stiff enough. Maybe my brass sluggs need to wear in a bit.. not sure as I have not had them installed that long.

It holds the quill at the top, but as soon as it moves, it sometimes wants to fall all the way to to the bottom, especially if the handle is on the down swing of its arc.

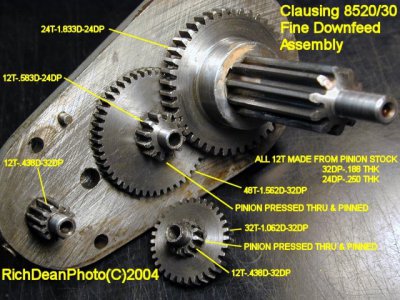

I found a 4" chrome wheel on amazon and drilled it to fit the fine feed and pinned it to match. Works very well although I haven't adapted my boring head to 2MT yet.

Clausing still has some parts available, although they can be pricey. Be sitting down when you call. Hard to make parts can be worth it. If they don't have the parts, they sometimes have drawings they can send you so you can make replacements yourself. Some are posted here.