- Joined

- Jan 22, 2022

- Messages

- 128

I just picked up the last piece of my home shop. The Clausing 8520. I probably overpaid. $2500 in the Detroit area but I’m happy with my purchase and I’m an impatient person. Along with my Langmuir Pro CNC plasma cutter, craftsman 12 inch lathe, press brake, TIG and MIG… I’m going to be entertained for a while.

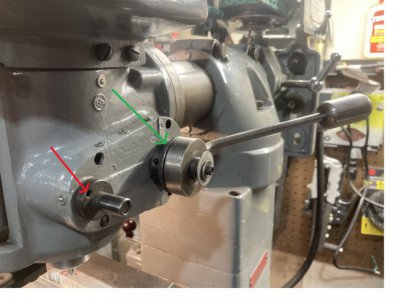

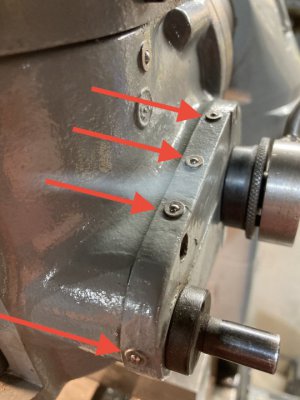

I have a couple questions about my 8520. I need a hand wheel for the quill. How does it attach?? I don’t see anything for it to grip on to.

Also, when operating my mill the quill slowly feeds down by itself. Is there a lock for it or do I have something worn out?

Can anyone identify this vise? It’s massive. I was going to get Kurt vise but this thing seems pretty legit. I might just leave it as is.

It runs pretty good! I love them Accu-Link belts and immediately put one on. Big difference. Now I need to clean and oil it up… and make something. My plans are to add a power feed and DRO eventually.

edited for more questions

The 8520 came with some cheap swivel casters that were definitely NOT rated for the weight. I want to get some heavy cast iron casters. Is this a terrible idea?? If so can anyone recommend good adjustable feet?

Can anyone recommend a decent carbide indexable end mill in MT3?

I have a couple questions about my 8520. I need a hand wheel for the quill. How does it attach?? I don’t see anything for it to grip on to.

Also, when operating my mill the quill slowly feeds down by itself. Is there a lock for it or do I have something worn out?

Can anyone identify this vise? It’s massive. I was going to get Kurt vise but this thing seems pretty legit. I might just leave it as is.

It runs pretty good! I love them Accu-Link belts and immediately put one on. Big difference. Now I need to clean and oil it up… and make something. My plans are to add a power feed and DRO eventually.

edited for more questions

The 8520 came with some cheap swivel casters that were definitely NOT rated for the weight. I want to get some heavy cast iron casters. Is this a terrible idea?? If so can anyone recommend good adjustable feet?

Can anyone recommend a decent carbide indexable end mill in MT3?

Last edited: