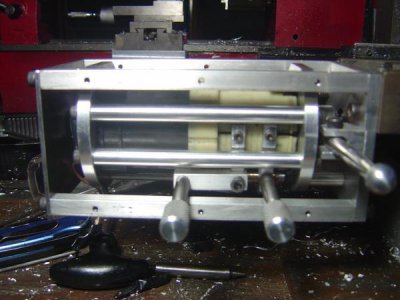

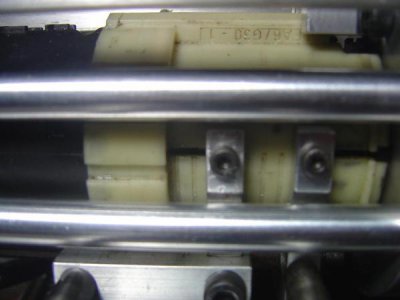

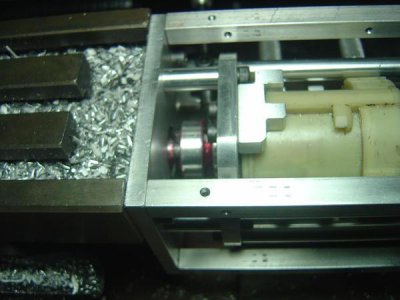

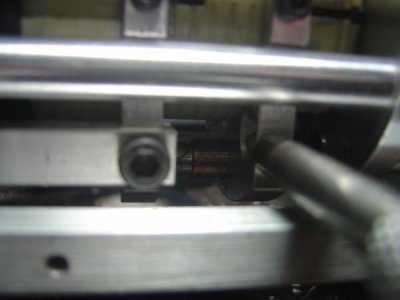

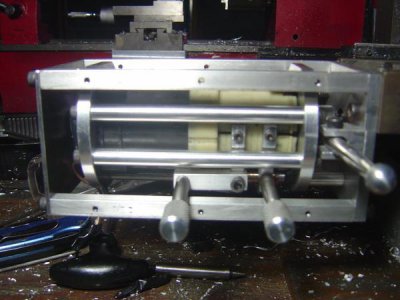

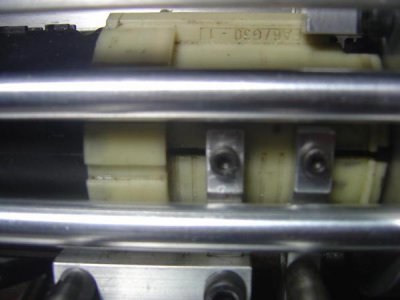

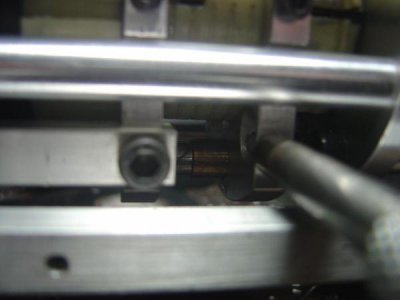

here is a power feed i have built from an old dewalt xrp drill. has 3 speeds on the tranny. will get some better pix of all the workings soon.

http://www.youtube.com/watch?v=G-QZ4Y5pVlo

http://www.youtube.com/watch?v=XWve_gJH6Dw

http://www.youtube.com/watch?v=G-QZ4Y5pVlo

http://www.youtube.com/watch?v=XWve_gJH6Dw