- Joined

- Feb 4, 2015

- Messages

- 18

Hi Guys

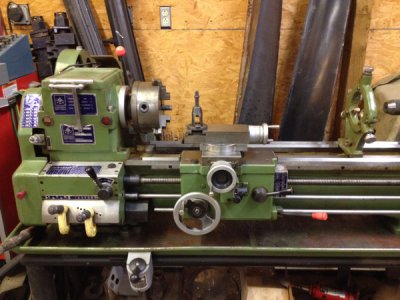

this is my Jet 1236PS, that I've had for quite some time. I works great, but I have small issues with it.

anyways, years ago, I had a problem where it blew some capacitors. So I called a local electrical shop and took the motor and switch to them. He said the motor looked fine, but I needed a new switch, and of course some new capacitors. So, I couldn't find a factory switch for it so I purchaced a good switch and had to mount it on the chip tray. Now fast forward a year ago I blew a few capacitors and took it to another company to check things out and they found nothing. Well a friend was by and best he figured is it is this little aluminum disc that kicks the motor into a owed speed till the catches up to speed. Now I may be explaining it wrong, but as we all know factory parts for these are very hard to come by, and I would like to fix this motor or get a good replacement and really would like to put the switch back to factory. Now no real rush, because it runs ok ( 98% ) of the time.

this is my Jet 1236PS, that I've had for quite some time. I works great, but I have small issues with it.

anyways, years ago, I had a problem where it blew some capacitors. So I called a local electrical shop and took the motor and switch to them. He said the motor looked fine, but I needed a new switch, and of course some new capacitors. So, I couldn't find a factory switch for it so I purchaced a good switch and had to mount it on the chip tray. Now fast forward a year ago I blew a few capacitors and took it to another company to check things out and they found nothing. Well a friend was by and best he figured is it is this little aluminum disc that kicks the motor into a owed speed till the catches up to speed. Now I may be explaining it wrong, but as we all know factory parts for these are very hard to come by, and I would like to fix this motor or get a good replacement and really would like to put the switch back to factory. Now no real rush, because it runs ok ( 98% ) of the time.