- Joined

- Apr 2, 2014

- Messages

- 17

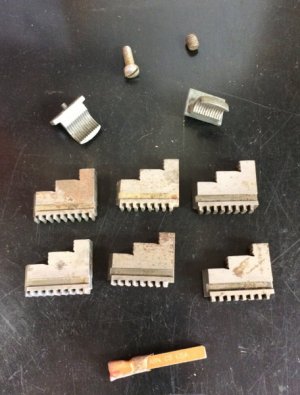

I recently purchased this Atlas 618 lathe. It is in working condition ... but has a few issues. I will be needing your help with getting the machine to run as it should. I will be posting my questions in this thread, as they arise from my inspection/testing.

I have read just about everything I could find on this site regarding the 618 ... but being a complete novice ... a lot of the information is a bit over my head.

For today ... I will just post the pictures identifying the lathe. The questions will come later. Thank you for taking the time to read this post.

I have read just about everything I could find on this site regarding the 618 ... but being a complete novice ... a lot of the information is a bit over my head.

For today ... I will just post the pictures identifying the lathe. The questions will come later. Thank you for taking the time to read this post.