- Joined

- Feb 8, 2014

- Messages

- 11,144

Jim, are you saying that he could add the fanuc unit to his centroid, and that they would be able to communicate and know when to change tools, and know that the tool has been changed?

To do ATC I need to buy that option/unlock - But it's not too pricy if I recall. Just checked - It's $280. but this software is crazy cool & easy to use. I now just fly thru the keys. And it's so intuitive at times. I'm an IT guy - And a DOS based program at first blush made me wince a bit.... fret not. solidm robust, and very easy to learn. (with you guys here of course!).

I wonder if the ATC's just communicate over RS 485 or something? anyway- I'll pop on a thread when I did into this a bit more.

An interface would have to be created. I would rip out the original controls and put in a small PLC to handle the comms and operation. It only takes about 4 to 6 I/O points to run the Fanuc tool changer. I'm doing it with the Galil controller on Alloy's machine. I'm sure the Centroid controller can send an RS232 or 422 signal out, if not, a digital output and input could work.

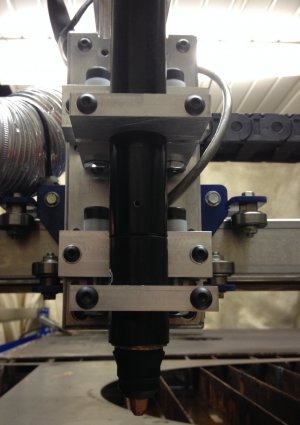

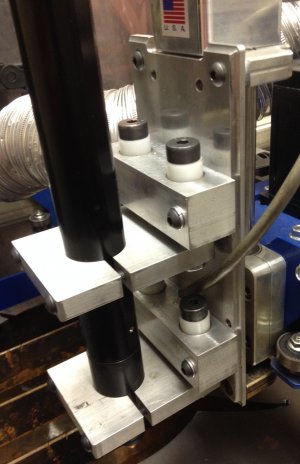

Nice design and execution. Very professional!

Nice design and execution. Very professional!