Stephan - How you are making out on your lathe?

Well it has been a while since last post. Left off with my cross slide screw bent is several places beside it had wear in the middle could feel with new nut. Was going to try to turn ACME threads and make a new screw. Look at this project really need a follower to keep the threading operation from defecting the shaft.

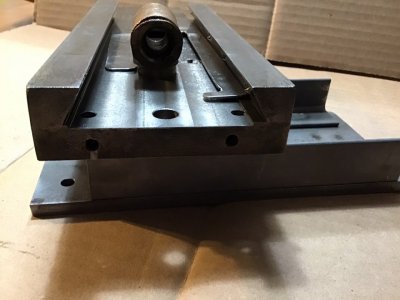

Checked in with Tom at Clausing but no longer have the 100 Mk3 cross slide screw but they still produce the cross slide screw Part# Q-352 for the 4800 series and several other models. For $189 for a new screw, gear and nut, that price did not seem that bad consider the extra tooling and labor. Looking at the other Clausing parts manuals, the saddle, cross slide and compound share the same parts with the 200, 6300, 5300 and several other lathes. The 5900 is a different animal... Will follow up more pictures this week.