- Joined

- Dec 3, 2014

- Messages

- 497

I was speaking with the owner of a commercial machine shop last night and found out that he too sometimes has the same issue I do... the issue I hate more than anything.

A little more about his business, he makes machined parts for various industries. He has two cnc lathes (I got to see one run, cool) two cnc mills, manual mills and lathes, etc and outsources things like bending and anondizing.

So many hobbyists too rely on outsourcing things we just can't do such as water jet cutting, EDM work, anodizing to name a few, and so so often when we reach out to small and medium sized businesses seeking their services those businesses either don't respond at all our are dismissive of our requests.

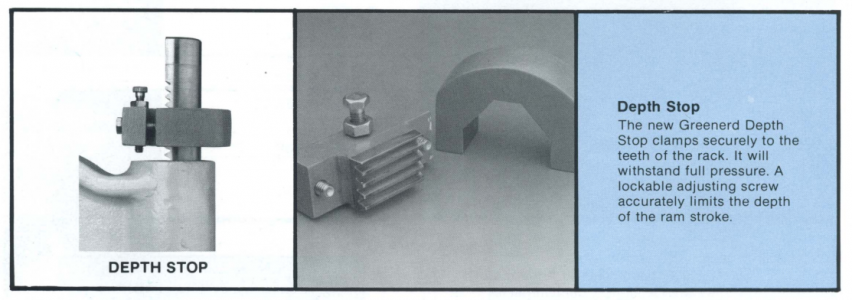

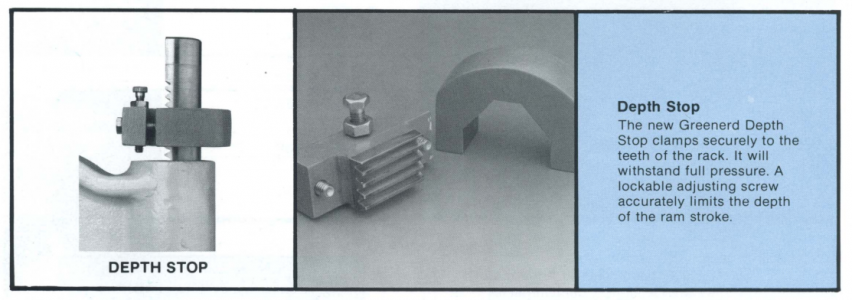

Case in point, back on May 2, 2022, at 11:39 AM I reached out to the sales department of Greenerd to inquire if they still produce and sell arbor presses and stops after seeing their literature. I want a stop for my 3E press. The website does not make it clear one way or the other.

They did not even acknowledge my email. Zip nada, nothing. I have a word for those types.

The same applies to a local heat treating company I requested a quotation from for cryogenic HT for wood lathe bowl gouge blanks I ground

A little more about his business, he makes machined parts for various industries. He has two cnc lathes (I got to see one run, cool) two cnc mills, manual mills and lathes, etc and outsources things like bending and anondizing.

So many hobbyists too rely on outsourcing things we just can't do such as water jet cutting, EDM work, anodizing to name a few, and so so often when we reach out to small and medium sized businesses seeking their services those businesses either don't respond at all our are dismissive of our requests.

Case in point, back on May 2, 2022, at 11:39 AM I reached out to the sales department of Greenerd to inquire if they still produce and sell arbor presses and stops after seeing their literature. I want a stop for my 3E press. The website does not make it clear one way or the other.

They did not even acknowledge my email. Zip nada, nothing. I have a word for those types.

The same applies to a local heat treating company I requested a quotation from for cryogenic HT for wood lathe bowl gouge blanks I ground

Last edited: