Biggish update! I got a lot of weird little things done, some I have pix of, some didn't come out.

One that the pic didn't come out was the exhaust piping inside the smokebox. It was pretty much a 3 handed job with room for none. Things got really interesting when the stupid channel locks slipped, hit the trouble light and sprayed broken glass and sparks in my face... there's a REASON I always get polycarb lenses!

If you remember the test fire from 2010, then you'll recall this boiler doesn't draw worth a hoot (it was originally designed for an undermounted, with the typical short chimney) So in order to help the boiler draft better I decided I needed to lengthen the stack.... Just how tall was the question. The piece I had to splice on was just a LITTLE BIT too long

I cut it off the same height as the top of the governor. But it still wasn't right. (A spark arrestor will be made from this wing fryer basket I found at a flea market for 50c, more on that in a day or three)

So I tried once again, this time I think it looks acceptable. If you've ever used little Ridgid pipe cutters to do household plumbing, here's one on steroids... It will cut up to 6"

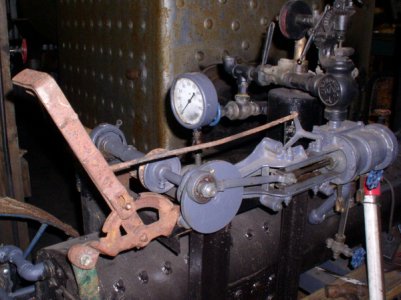

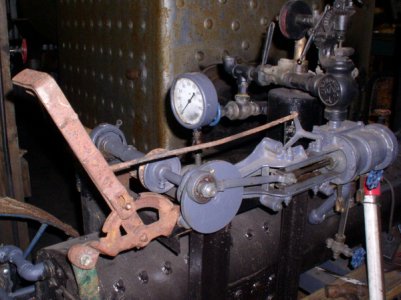

On to something interesting. I got this lever off the same manure spreader the wheels came from. It will make a dandy Johnson bar.

And hooked up. The notches for forward and reverse are only about an inch apart.

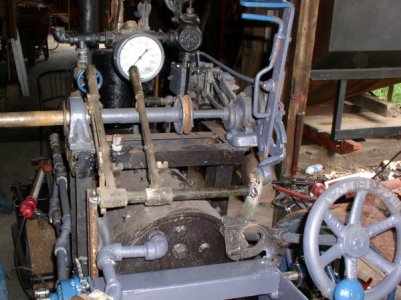

Some very light used 3" channel made a good looking countershaft shield

Then I worked on the feedwater piping some more, but didn't take a pic

I thought long and hard about how to do the depressed section of the platform. I really wanted to use 5/4 wolmanized like the upper platform, but also needed to make the whole thing strong enough to be used as a tie down point when the roller gets trailered. Well, I had this bit of diamond plate seasoning in the shed, so I decided to go the lazy route and just use it to make the depressed section. I may bolt wood to it later.

The bunker supports are done. They hold my weight without moving. I need to get a couple bulkhead connectors yet, before I mount the hotdog coolers, but I'm actually pleased with how it looks so far.

I had to quit early because I had a meeting, so that's all for this update. thanks for looking!