I've got a little tiny knick inside my TS. I tried a little high grit paper to just touch it but to no avail. The machine is almost new. Also thought about the reamer but man I don't want to mess it up.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

MT3 Reamer

- Thread starter matthewsx

- Start date

Bearden P The Hardinge I have is a HLV -H . Year is around 1986 just guessing . The tail stock is a number 2 Morse taper. The reamer took out the burrs ,but the spindle was too hard for the reader to really cut. I was happy to remove the burrs so all is well. If you would like to use the reamer your welcome to .. Drop me a pm and we can discuss it there.

- Joined

- Nov 9, 2015

- Messages

- 427

I did the same thing with the spindle bore on my Atlas 10F several years ago. Ground down the high spots with a Dremel, then followed with roughing and finishing import reamers. I did the reaming freehand without using the tailstock to hold the reamers. It took a long time, but eventually got there.I did a clean-up on my Atlas spindle and tailstock tapers with Russian reamers. The spindle and tailstock material was very hard, and it was rough on the reamers to simply clean the tapers up. It worked great, but any more than a micro clean-up would have destroyed the reamers. You might need to anneal.

John: If you're in CA now, or want them sent there, I might be the closest to you postage-wise. Let me know if you want to borrow the reamers. Bill

- Joined

- Jan 2, 2019

- Messages

- 7,115

I have one coming but will let you know if it doesn't work out, USPS flat rate really makes this kind of stuff easy. If anyone needs "single use" tools like this I think we should really take advantage of this forum. Everyone I've met on here is definitely the sort I'd lend a tool to....I did the same thing with the spindle bore on my Atlas 10F several years ago. Ground down the high spots with a Dremel, then followed with roughing and finishing import reamers. I did the reaming freehand without using the tailstock to hold the reamers. It took a long time, but eventually got there.

John: If you're in CA now, or want them sent there, I might be the closest to you postage-wise. Let me know if you want to borrow the reamers. Bill

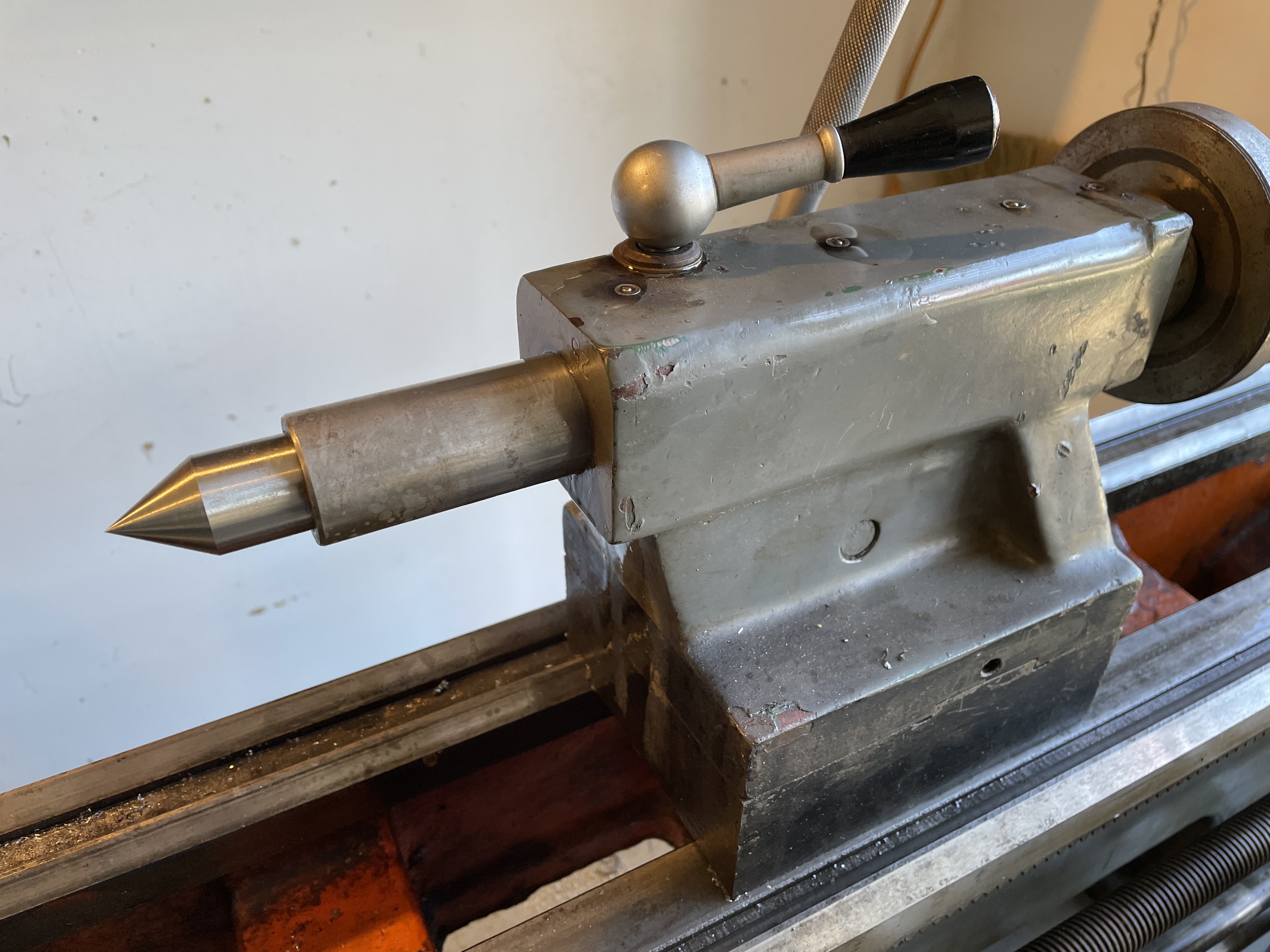

View attachment 377749View attachment 377750

I will have some materials to trade soon as well

John

- Joined

- Nov 24, 2014

- Messages

- 3,569

@matthewsx

I'd be interested in knowing how you go about the project and how it turns out. I think you should start a project thread or put the story in the POTD thread. I don't think I've ever read about someone changing the TS taper.

Good luck.

I'd be interested in knowing how you go about the project and how it turns out. I think you should start a project thread or put the story in the POTD thread. I don't think I've ever read about someone changing the TS taper.

Good luck.

- Joined

- Jan 2, 2019

- Messages

- 7,115

Thank you @seasicksteve I finally got it done....

Had to order an MT4.5 adapter sleeve from Grizzly and had some time today so I enlarged my tailstock taper to MT3

I'll put the reamer in the mail ASAP

Thank you,

John

Had to order an MT4.5 adapter sleeve from Grizzly and had some time today so I enlarged my tailstock taper to MT3

I'll put the reamer in the mail ASAP

Thank you,

John

- Joined

- Nov 24, 2014

- Messages

- 3,569

- Joined

- Jan 2, 2019

- Messages

- 7,115

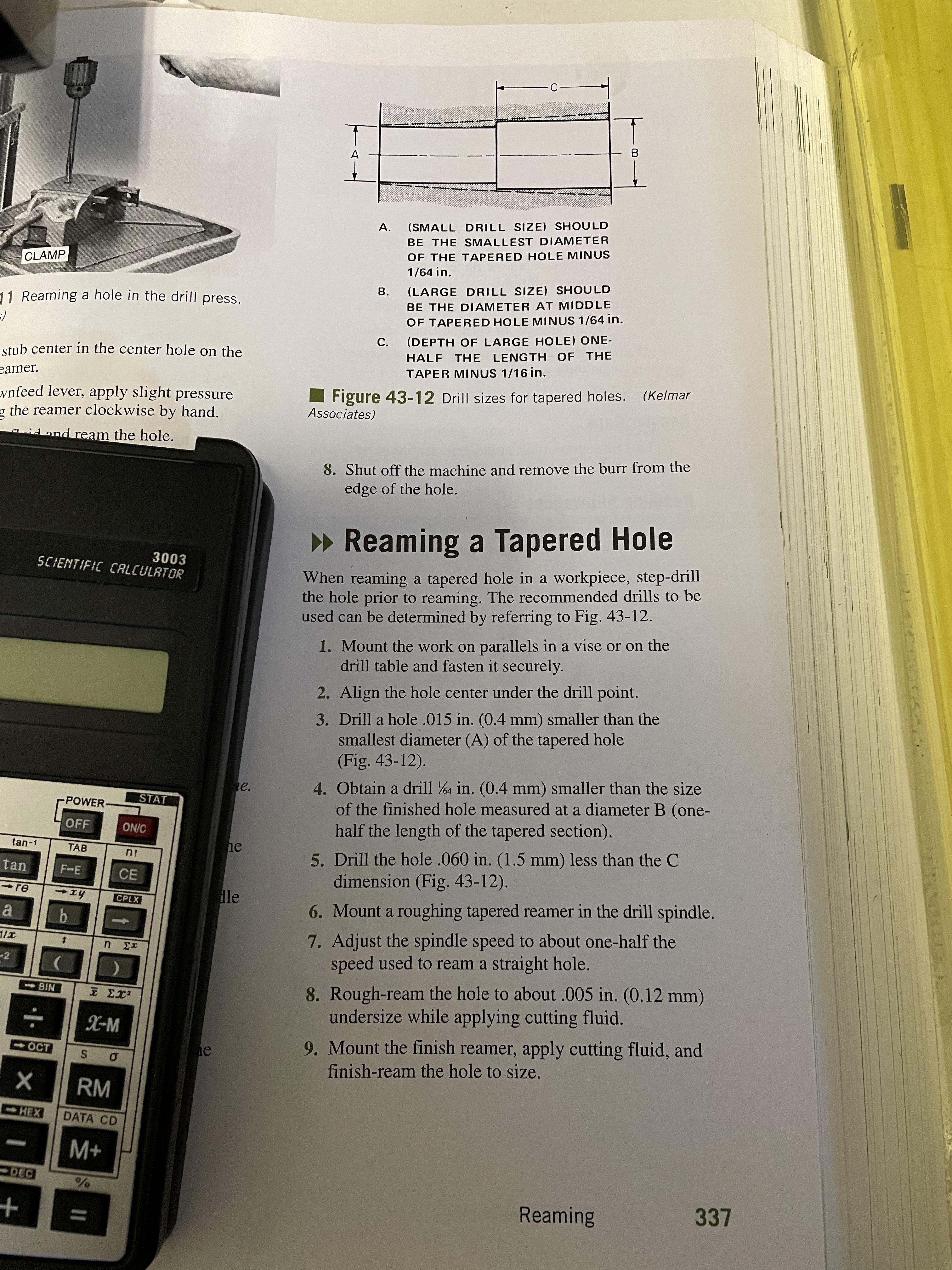

Thanks, it's Technology of Machine tools recommended by someone on here.

John

John

- Joined

- Oct 11, 2016

- Messages

- 4,004

@Nutfarmer @matthewsx @pontiac428

I really feel that it is important that I dispel this popular myth: Tail stocks are NEVER hardened. The odd time in old lathes where the barrel were cast iron there may have been an inclusion or 2, but that's for lathes around WW1 era.

I have rebuilt all kinds of lathes from all kinds of eras and done extensive research on this, and it just has never happened. If you think about it for a minute, a lot of dead centres are hardened completely along the length. if the tailstock were hardened there would be no grab at all.

I'm really sorry if one or more of you has been taught this old saw, but every machine rebuilder I have asked has also confirmed that none are hard.

I really feel that it is important that I dispel this popular myth: Tail stocks are NEVER hardened. The odd time in old lathes where the barrel were cast iron there may have been an inclusion or 2, but that's for lathes around WW1 era.

I have rebuilt all kinds of lathes from all kinds of eras and done extensive research on this, and it just has never happened. If you think about it for a minute, a lot of dead centres are hardened completely along the length. if the tailstock were hardened there would be no grab at all.

I'm really sorry if one or more of you has been taught this old saw, but every machine rebuilder I have asked has also confirmed that none are hard.