- Joined

- Aug 24, 2017

- Messages

- 6

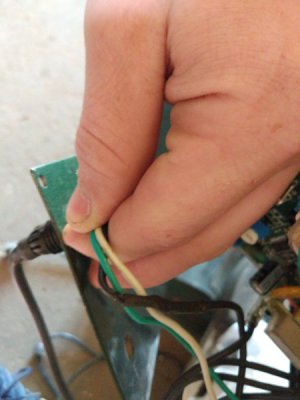

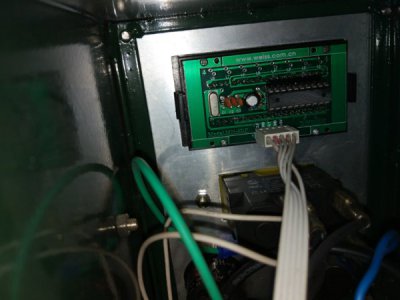

Hi all, I recently received a mini milling machine from one of my good friends and ever since I got it, the motor has not started up (part of the reason why I got it free). It's a Craftex CT129N, which I had never heard of until now. I assume it's some sort of off brand Chinese thing. I have always wanted to get into machining, and I do have some experience from school, so I thought now would be the perfect opertunity to get started. Anyways, when I learned that the motor was not turning on, I started to diagnose some problems. First off, when I opened the dro, the negative wire coming from the wall was disconnected somehow, so at first I thought that was the problem, so I fixed it by soldering it back together and heat shrinking it (pictured below).

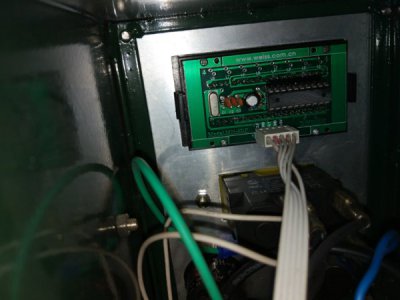

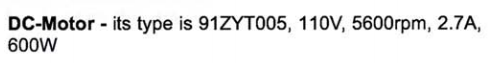

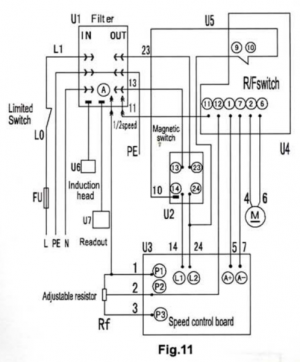

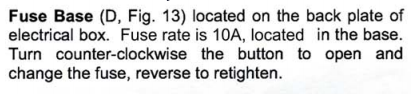

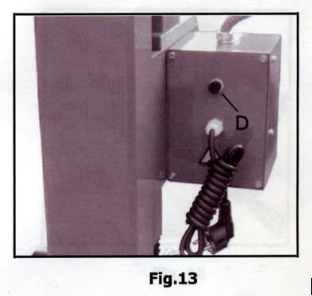

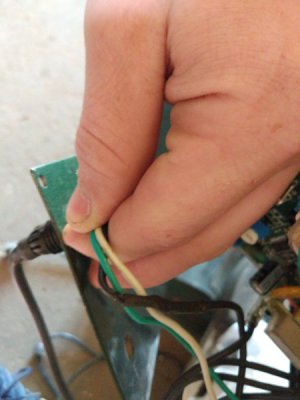

I also discovered that the data cable for the rpm digital screen, was disconnected. After I have fixed those issues, it didn't seem to affect the motor, but it did at least enable the digital Rpm readout to work. After that I started to take a look at the motor and connections to the motor. I turns out according to my owners manual there is an entire fuse missing from the dro. Even more interesting is that I can't find anywhere where the fuse would have gone!? A picture is provided to further your understanding. I also just discovered that there seems to be a ground wire that is missing from the motor. This all seems kind of strange to me, it seems like someone messed with it. If you know anything about the fuse and where it's so post to go and how it gets wired in, or if you know anything about how to wire in the ground cable for the motor please let me know. Thanks you for you time and thought, Anton Schuster

I also discovered that the data cable for the rpm digital screen, was disconnected. After I have fixed those issues, it didn't seem to affect the motor, but it did at least enable the digital Rpm readout to work. After that I started to take a look at the motor and connections to the motor. I turns out according to my owners manual there is an entire fuse missing from the dro. Even more interesting is that I can't find anywhere where the fuse would have gone!? A picture is provided to further your understanding. I also just discovered that there seems to be a ground wire that is missing from the motor. This all seems kind of strange to me, it seems like someone messed with it. If you know anything about the fuse and where it's so post to go and how it gets wired in, or if you know anything about how to wire in the ground cable for the motor please let me know. Thanks you for you time and thought, Anton Schuster