Keep in mind you don't need 75% thread depth for most of what you are making, go up one drill size for the tap drill and you'll need less torque. I use a strap wrench or the chuck key to turn the chuck against the tap on my 7x, holding the tap in a tap wrench with a follower. Make yourself a a MT2 tap follower, it' s a good project and will save on valuable bed length!

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mini Lathe Thread Tapping - Not Enough Torque

- Thread starter MaverickNH

- Start date

- Joined

- Feb 1, 2015

- Messages

- 9,616

With the tap follower, it is spring loaded so it automatically advances as the cut threads pull it in.So, does one just gradually advance the tap held by a chuck in the tailstock, while rotating the chuck by hand or chuck key?

- Joined

- Dec 18, 2019

- Messages

- 6,458

I added a picture to my previous post.

There is no way all of that fits on a 7x12 mini lathe!I added a picture to my previous post.

- Joined

- Jun 7, 2013

- Messages

- 10,094

Typically, I do not tighten the tailstock to the bed, and push it along until the tap starts to engage the cut, usually I power tap, but on small taps, I may start them under power, but continue by pulling on the drive belt; my 9" lathe is overhead drive. On my 19" lathe it is all power tapping, allowing a bit of slip in the Jacobs chuck to avoid breaking taps, a rare occourance if good quality sharp HSS taps and appropriate lubricant are used, my favorite is TapMagic.So, does one just gradually advance the tap held by a chuck in the tailstock, while rotating the chuck by hand or chuck key?

- Joined

- Dec 18, 2019

- Messages

- 6,458

I've done it on a 7x16 mini-lathe. I've tapped an M8 for sure on a mini. That's a larger lathe 10x22, so I could use a larger tap wrench. On the mini you'd have to slide the tap wrench handle around every 1/2 turn. It would get tedious, but it's doable.There is no way all of that fits on a 7x12 mini lathe!

It was quicker to set up the "photo shoot" on the 10x22 than the mini. I mean, I went down to the shop and set up the photo for the OP.

- Joined

- Jan 4, 2021

- Messages

- 1,806

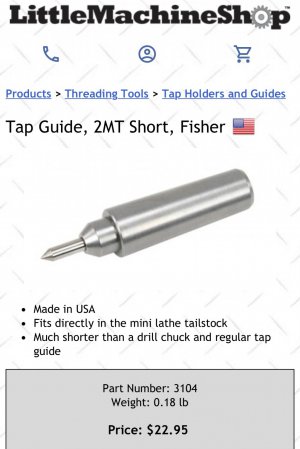

LMS also has MT2 Tap Followers:Keep in mind you don't need 75% thread depth for most of what you are making, go up one drill size for the tap drill and you'll need less torque. I use a strap wrench or the chuck key to turn the chuck against the tap on my 7x, holding the tap in a tap wrench with a follower. Make yourself a a MT2 tap follower, it' s a good project and will save on valuable bed length!

- Joined

- May 7, 2023

- Messages

- 1,357

Two things:One of these are handy. Tap Follower I'm sure you can get one elsewhere, but since you know LMS, I posted it.

I wouldn't power a tap using a mini-lathe. 1) Not enough guts, 2) No auto-stop or back off when you hit bottom. Not stopping at bottom is bad news. Just tap by hand using a good HSS tap, which usually is not what you buy in a kit. Buy taps as you need them, and after a while you will have a good collection. Or buy some used quality ones in quantity and sort them out (before using them for something important). A good tap is a pleasure to use, as it cuts cleanly and efficiently.

A tap follower is an excellent home shop project.

Also we have a dedicated (read worn/crappy) chuck we use in the tailstock just got this purpose.

The key is to not over tighten the chuck to the point that you will break the tap. You can leave the chuck key in it tightened loosely yet tight enough to start, then tighten the chuck a little until it just holds.

Some would say this wipes out the markings on the tap shank and other things, but taps are consumables and I rarely dull one before chipping the lead backing it off or by other means.

- Joined

- Nov 6, 2012

- Messages

- 127

This unit turned out to be too large for my mini-lathe, but I’ll bring it to our Makerspace to use on our South BendKind of like this?

I have a MT4 tailstock.

You can buy these or make them.

Super handy.

The chuck takes up a bit too much space on my mini lathe, so I’ll try the LMS MT2 option below.Not with a tap follower.

Install the tap follower in the chuck in the tail stock. Put tap in tap holder. Put tap in hole of part, which is held by the main chuck. Align tap wrench such that the tap follower point is in the divit of the tap wrench. Adjust tail stock so that the tap follower spring is compressed. Hold tap still and rotate main chuck, or hold main chuck and turn tap. The spring loaded tap holder simply centers the tap to the bore.

View attachment 465850

BTW, what’s that tooling rack on your splash guard - bought or made?

On the way - the East Coast where I live is too far from the West Coast, where LMS is located

The common lament: Only after placing an order, do I find another item to buy!

- Joined

- Dec 18, 2019

- Messages

- 6,458

Tooling rack is 1.5" 80/20 aluminum with printed tool holders. It really has helped slow down the onset of total chaos in the shop. AXA size. If you want to print some I would share the stl files. There's the holders and some wedges which tilt the 8020 up by 5 or 10 degrees, so the tool holders don't slide off by accident or vibration.This unit turned out to be too large for my mini-lathe, but I’ll bring it to our Makerspace to use on our South Bend

The chuck takes up a bit too much space on my mini lathe, so I’ll try the LMS MT2 option below.

BTW, what’s that tooling rack on your splash guard - bought or made?

On the way - the East Coast where I live is too far from the West Coast, where LMS is located

The common lament: Only after placing an order, do I find another item to buy!