- Joined

- Nov 6, 2012

- Messages

- 128

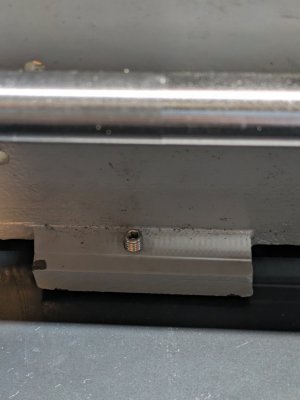

I have a heavy old wooden desk I’ve put my LMS 7x12 mini lathe on, with a sheet of 1/8” oil-resistant rubber under, with the supplied rubber feet. As I’ll be converting that lathe to a 7x16 shortly, I’m reconsidering the workbench mounting.

I could rough-level that desk with shims under the legs, replace the rubber sheet with a steel plate, remove the rubber feet and bolt the bed down metal-to-metal, using shims to level.

Is that overdoing it?

BRET

I could rough-level that desk with shims under the legs, replace the rubber sheet with a steel plate, remove the rubber feet and bolt the bed down metal-to-metal, using shims to level.

Is that overdoing it?

BRET