-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Milling tree's for lumber and wood for projects.

- Thread starter woodtickgreg

- Start date

Just got my own setup. Looks like the same make although I have the smaller version. A friend cut down a cherry tree in his backyard and I couldn't let it go to waste. Looks like I will get about 150 bd ft of wood. The first cut is made along a guide.

Some beautiful ccherry this log will pay for the rig.

Dave

Some beautiful ccherry this log will pay for the rig.

Dave

- Joined

- Aug 7, 2013

- Messages

- 655

It's a McCulloch saw, 100cc, it was made by partner in Sweden, she's all metal and a torque monster. Parts are not available for this saw any more so when she wears out I will be looking for a new power head. I used this saw when I ran a landscape business and processed firewood, I've had it for better than 20 years and she's still going strong, I maintain her well. Another thing about the chain is I custom grind the angles, they come at about 10 degree and I change it to about 18 degree, it's a good compromise of speed and finish quality.

This one?

http://www.acresinternet.com/cscc.n...baaa3483b43eb4d988256afd004da8d2?OpenDocument

- Joined

- Jun 22, 2012

- Messages

- 1,552

Yup, it's a gravity fed oiler, pulling a chain this long and under the stress it is under all the lube you can get is a bonus. I had to drill 2 holes in the hardened bar for the feed fitting and nut.beautiful. . what is the thing on the right hand end of the frame ? oiler ?

- - - Updated - - -

Yup, that's it.

- - - Updated - - -

Yes you are correct, the first cut is very important as each succesive cut follows the one before. The first slabbing cut is done with a pair of slabbing brackets. They are just 2 straight 2 x 4's connected with an aluminum channel with screws. It is screwed onto the log for the first cut and then removed, you can cut logs as long as the straight 2 x 4's are. I'll se if I have a pick of the slabbing brackets set up.So Greg, how do you make that first cut? I would think it is all important on the first. Wouldn't it need to to be dead straight?

- Joined

- Jun 22, 2012

- Messages

- 1,552

Randy, here's a pic of the slabbing bracket attached and a pic after the first cut and the slab removed. The first cut is always like christmas to me, it might be something special like this log was, or just plain usable lumber like you buy at the lumber yard, or rotten and no good, you never know. This one was a special ambrosia maple log 9' long and 30" or so at it's widest point.

- Joined

- May 26, 2013

- Messages

- 90

Wow! So need to see a short video, showing say, the first two cuts, which will answer a LOT of questions in the readers minds.

Not being a woodworker, I didn't think this post would interest me at all.... Wrong!

My mind is going all sorts of places now.

Top post!!!

Not being a woodworker, I didn't think this post would interest me at all.... Wrong!

My mind is going all sorts of places now.

Top post!!!

- Joined

- Mar 14, 2013

- Messages

- 736

Mail me a hunk of it?

- Joined

- Jun 22, 2012

- Messages

- 1,552

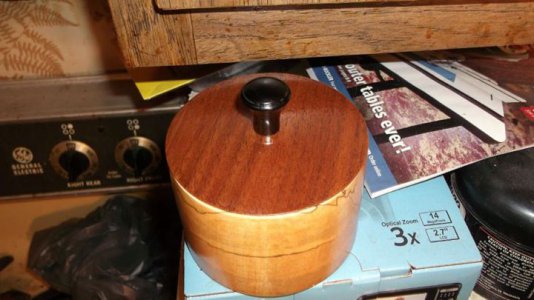

I only kept 2 chunks of it for turning, all the rest I left with my friend, I just milled it for him. are you a wood worker as well?Mail me a hunk of it?

- Joined

- Mar 14, 2013

- Messages

- 736

I only kept 2 chunks of it for turning, all the rest I left with my friend, I just milled it for him. are you a wood worker as well?

Yeah, I am the one that was rebuilding the rockwell 6X48 belt sander, that used the old sink knobs for the delta sander. Just brought a Uni-saw sight un seen, trusted the guy over the phone,has OE goose egg and dust door. See thread here.

http://www.garagejournal.com/forum/showthread.php?t=214994

Have been in the hospital a while now, everything is pushed back.

I have/had a little bit of ambrosia maple.Small ambrosia maple/walnut lidded box.