Note, plexiglass(aka perplex aka acrylic) does bend well with a heat gun or nichrome wire.

Lexan (aka polycarbonate) does not. Poly carbonate needs heated up very slowly to drive out the moisture and brough down slowly as well or it will get bubbles in it.

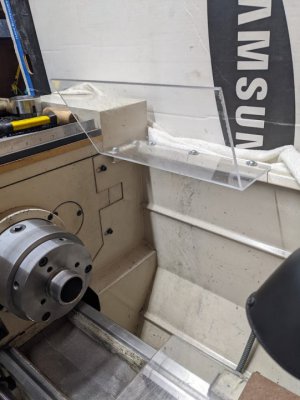

As previously noted, acrylic will shatter and is not a safety shield for large flying objects.

Also acrylic is very noted to crack at drilled holes if you use 118 degree drill bits. They make special drill bits to drill and the edges of the holes should be touched with a countersink to deburr and not allow a stress riser.