- Joined

- Apr 28, 2013

- Messages

- 84

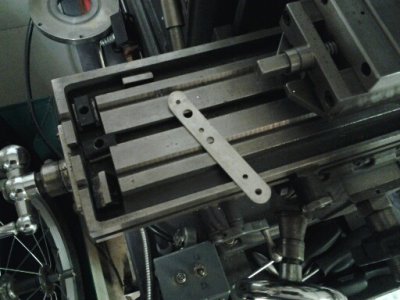

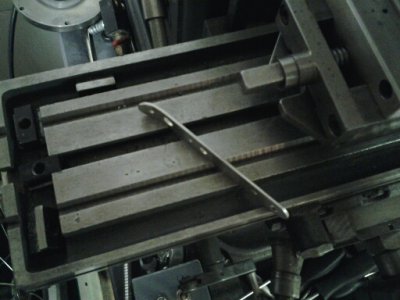

I'm trying to engage the pin for the back gear and I'm a bit stumped. Found some pics that make it look like a small flat piece of steel with a notch should go in there to push/pull the pin, but the clearance on mine is practically non-existant. Is the face of the gear supposed to be so #@$%*& close to the casting? I've got just a hair more than 1/8" clearance. Can someone take a look at the pic and tell me if it looks normal? I'm starting to wonder if someone assembled the spindle wrong or something.

Would it have been too much to ask for Atlas to provide a little hole in the front of the casting to reach through?

Would it have been too much to ask for Atlas to provide a little hole in the front of the casting to reach through?