- Joined

- Sep 3, 2012

- Messages

- 311

I am about to purchase a center cutting end mill to machine brass.

Should I use a 2 flut end mill?

tks

Should I use a 2 flut end mill?

tks

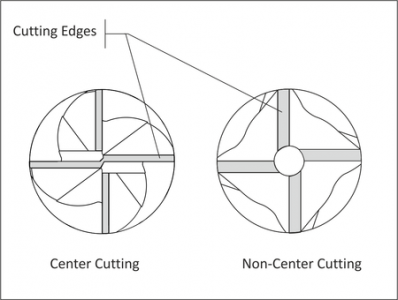

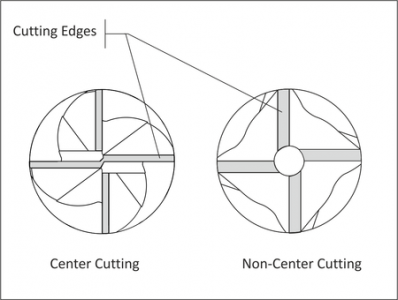

You mean "over-center-cutting". "Over-center-cutting" means that you can plunge with it because of its geometry at the center of its flat bottom which has sharp edges. These are more often referred to as slot-drills (at least here in ZA). Whereas end mills have a hollow geometry at the center of their flat bottom and can not plunge very deep thus they are more commonly used for cutting the "ends" of material and not plunging through the top.

I would like point out that this is a classic example of how terminology can vary from place to place. Here in the U.S., "center cutting end mill" is the common term, and "slot drill" is seldom heard on this side of the pond. None of the terms used in this thread have been incorrect. It is good to remember that there may be minor differences in terminology from place to place and that we all have to be respectful of those differences.

Never seen an end mill specifically ground for brass, but the drills I use on brass (and Plexiglas) have the cutting lip ground off, parallel to the axis. This results in a "scraping" action rather than a "shearing" action.

Ken

I am about to purchase a center cutting end mill to machine brass.

Should I use a 2 flut end mill?

tks