Measure and lay out a center on a worn shaft.

I can pick up a tad of the original dia near the base where it did not wear down. Aprox 1/2 of the shaft dia is intact.

Im just trying to figure out best way to mark the center

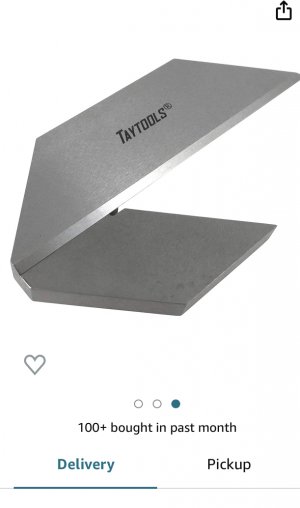

I know there are these tools , one I have is way to big. I dont know what sizes they come in.

My current approach will be best guess on dia ,half the dia with the caliper and scribe ad many lines ad I can?

I can pick up a tad of the original dia near the base where it did not wear down. Aprox 1/2 of the shaft dia is intact.

Im just trying to figure out best way to mark the center

I know there are these tools , one I have is way to big. I dont know what sizes they come in.

My current approach will be best guess on dia ,half the dia with the caliper and scribe ad many lines ad I can?