Hi everyone. My first post so please be gentle with me! I hope that someone familiar with the machine can clarify something for me. I am about to inherit a Maximat V10 in poor condition from a friend who passed away. It is under covers in his shed and I don't recall him ever using it.

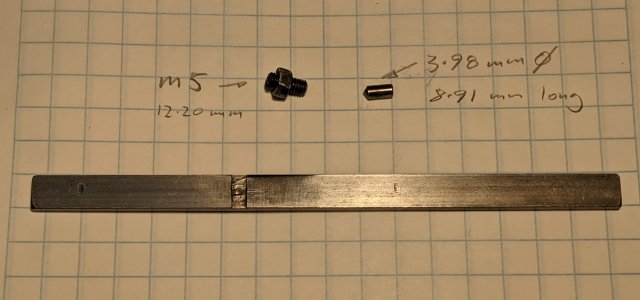

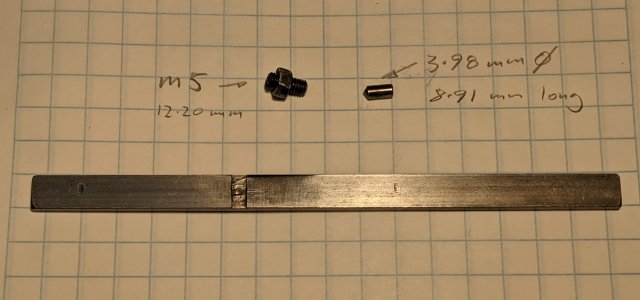

Anyway, I have some bits at home already including the compound slide and I noticed that the gib moved as the wheel was turned. On further inspection I found that of the four adjusting set screws, only three had lock nuts and only two had the pins that sit under the screws. This suggests that the slide has been disassembled at some point and two pins lost. I notice that the pins have a taper point on one end and these were fitted with the pointed end against the gib. I also note that the gib has a flat bottomed slot at one of the positions for the set screws....presumably to prevent the gib from moving along the slide.

My questions are:

1. Which direction should the pins be fitted? Pointed end to the grub screw or against the gib? ( I would have thought that at least the one against the slot in the gib would be flat end of the pin....but the marks in the gib look like the pointed end)

2. Are these a readily available part? If not then I may get a mate to make some up for me from 5/32" silver steel (drill rod)

Cheers from Down Under, Kim

Anyway, I have some bits at home already including the compound slide and I noticed that the gib moved as the wheel was turned. On further inspection I found that of the four adjusting set screws, only three had lock nuts and only two had the pins that sit under the screws. This suggests that the slide has been disassembled at some point and two pins lost. I notice that the pins have a taper point on one end and these were fitted with the pointed end against the gib. I also note that the gib has a flat bottomed slot at one of the positions for the set screws....presumably to prevent the gib from moving along the slide.

My questions are:

1. Which direction should the pins be fitted? Pointed end to the grub screw or against the gib? ( I would have thought that at least the one against the slot in the gib would be flat end of the pin....but the marks in the gib look like the pointed end)

2. Are these a readily available part? If not then I may get a mate to make some up for me from 5/32" silver steel (drill rod)

Cheers from Down Under, Kim